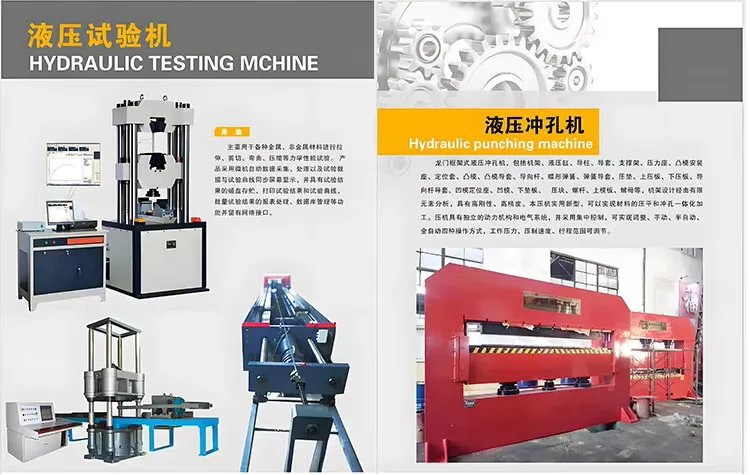

Factory 100 H Frame Hydraulic Press Metal Sheet Bending Hine

Factory 100 H Frame Hydraulic Press Metal Sheet Bending Hine

Couldn't load pickup availability

Product Introduction

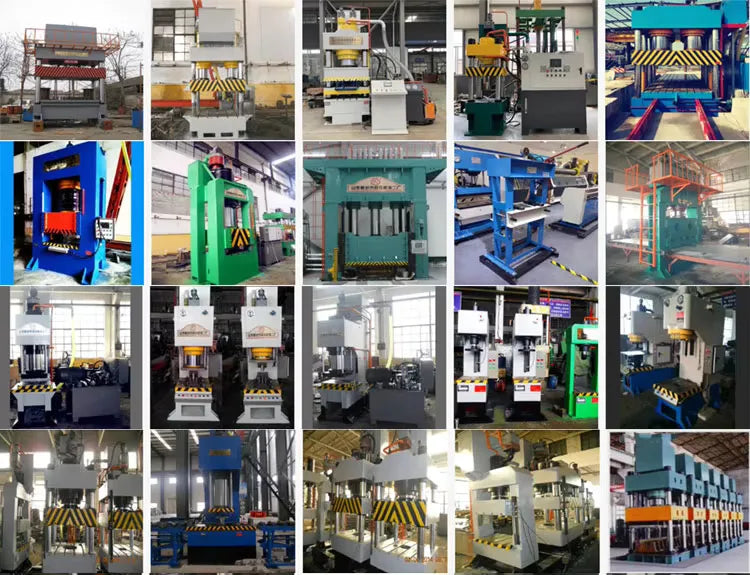

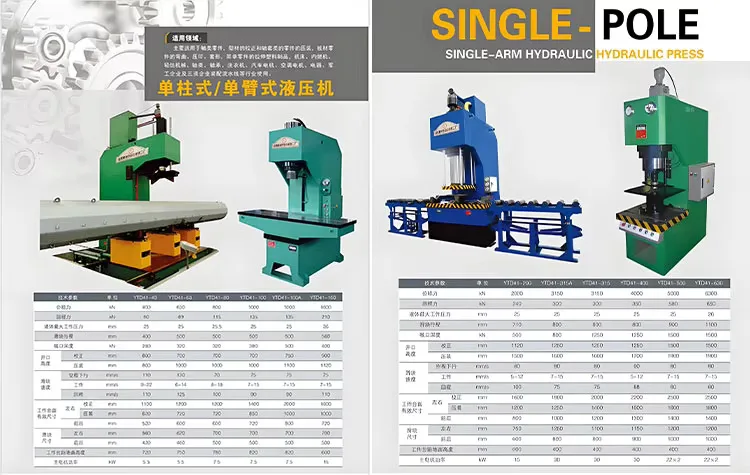

Our hydraulic press machine is a versatile and powerful tool designed to meet a wide range of industrial needs. The press head can move freely within the worktable plane (three coordinates), making it ideal for correcting medium and thick plates, structural components, and performing operations such as stamping and drawing. Exclusively manufactured by our company, this hydraulic press machine is extensively used in various industries, including construction machinery, forging machinery, heavy machinery, and shipbuilding. Additionally, we offer customization options to create dual gantry, multi-head presses, and various table sizes to meet specific user requirements.

Advantages

Versatile Operation: The press head's ability to move in three coordinates allows for precise correction of medium and thick plates, as well as the processing of structural components. This flexibility enhances the machine's usability for various tasks, including stamping and drawing.

Exclusive Manufacturing: Produced solely by our factory, our hydraulic press machine guarantees high-quality standards and reliable performance, ensuring you receive a product built to last.

Extensive Industry Applications: This machine is widely used in construction machinery, forging machinery, heavy machinery, and shipbuilding industries, making it a versatile tool for various industrial applications.

Customization Options: We offer the capability to customize the hydraulic press machine according to your specific needs. Options include dual gantry models, multi-head configurations, and various table sizes to suit different requirements and enhance productivity.

Robust and Reliable: Constructed with high-quality materials, our hydraulic press machine is designed to withstand the rigors of heavy-duty industrial use, providing long-lasting durability and consistent performance.

| Model | Capacity (KN) | Pressure (MPa) | Travel (mm) | Table Size (mm) | Dimension (mm) | Weight (kg) |

| HP-200 | 2000 | 31.5 | 300-405 | 940 x 580 | 1940 x 950 x 2530 | 2200 |

| HP-300 | 3000 | 31.5 | 300-405 | 1100 x 700 | 2250 x 1000 x 2600 | 2800 |

| HP-400 | 4000 | 31.5 | 300-405 | 1200 x 800 | 2500 x 1100 x 2750 | 3500 |

| HP-500 | 5000 | 31.5 | 400-450 | 1500 x 1100 | 2900 x 1200 x 3000 | 5500 |

| HP-630 | 6300 | 31.5 | 400-450 | 1800 x 1200 | 3200 x 1200 x 3500 | 6500 |

| HP-800 | 8000 | 31.5 | 500-650 | 1900 x 1300 | 3400 x 1300 x 3650 | 9500 |

| HP-1000 | 10000 | 31.5 | 500-650 | 2000 x 1400 | 3500 x 1400 x 3800 | 12000 |

| HP-1200 | 12000 | 31.5 | 500-650 | 2200 x 1600 | 3700 x 1500 x 4200 | 15000 |

| HP-1500 | 15000 | 31.5 | 600-700 | 2500 x 1800 | 3800 x 1600 x 4500 | 21000 |

| HP-2000 | 20000 | 31.5 | 600-700 | 3000 x 2000 | 4200 x 1800 x 4800 | 28000 |

| HP-2500 | 25000 | 31.5 | 700-800 | 3500 x 2200 | 4500 x 2000 x 5000 | 35000 |

| HP-3000 | 30000 | 31.5 | 700-800 | 4000 x 2500 | 5000 x 2200 x 5200 | 40000 |

1. What customization options are available for your hydraulic press machines?

We offer various customization options, including different tonnage capacities, worktable sizes, dual gantry models, multi-head configurations, and other special features to meet specific user requirements.

2. What are the key advantages of your hydraulic press machines?

- High Force Output: Capable of generating significant compressive force.

- Precision and Control: Offers precise control over the pressing force and speed.

- Versatility

- Durability: Constructed with high-quality materials for long-lasting performance.

3. What safety features are included in your hydraulic press machines?

Our machines are equipped with safety devices such as light curtains, safety interlocks, and emergency stop buttons to ensure operator safety.

4. How do I choose the right hydraulic press machine for my needs?

Consider the following factors:

- Required tonnage (force output)

- Size and shape of the workpieces

- Specific applications (e.g., punching, forming, molding)

- Speed and precision requirements

- Available workspace

5. What maintenance is required for a hydraulic press machine?

Regular maintenance includes:

- Checking and replacing hydraulic fluid

- Inspecting seals and hoses for leaks

- Lubricating moving parts

- Ensuring the hydraulic pump and motor are functioning properly

- Regularly inspecting safety devices

6. Can your hydraulic press machines handle heavy-duty tasks?

Yes, our hydraulic press machines are designed for heavy-duty applications and are extensively used in industries such as construction machinery, forging machinery, heavy machinery, and shipbuilding.

7. How can I get support if my hydraulic press machine needs service?

If your machine requires service, please contact our customer support team. We provide comprehensive support and maintenance services to ensure your equipment remains in optimal condition.

Share