1

/

of

6

FA206B Cotton Carding Machine for Spinning Machine

FA206B Cotton Carding Machine for Spinning Machine

Regular price

R 2,569,089.81 ZAR

Regular price

Sale price

R 2,569,089.81 ZAR

Unit price

/

per

Taxes included.

Shipping calculated at checkout.

Couldn't load pickup availability

We are a professional clothing factory with exquisite craftsmanship and advanced equipment. Our experienced team carefully crafts various high-quality clothing products, upholds craftsmanship, and serves numerous customers, which is trustworthy. There is a discrepancy between the current price and the actual price (configuration and logistics). To obtain product details and accurate prices, please add WA for confirmation WhatsApp : +86 15207187668 Email:ZheyaCoLtd@outlook.com

Our clothing factory's logistics and transportation packaging is highly reliable. We have specially designed packaging according to equipment specifications, with strong protection and stable fixation to ensure transportation safety and ensure that the equipment arrives intact.

WhatsApp : +86 15207187668

Email:ZheyaCoLtd@outlook.com

Cotton Carding Machine FA206B

Delivery speed up to 320 (m/min)

Delivery speed up to 320 (m/min)

Product display and advantages

Main Feature :

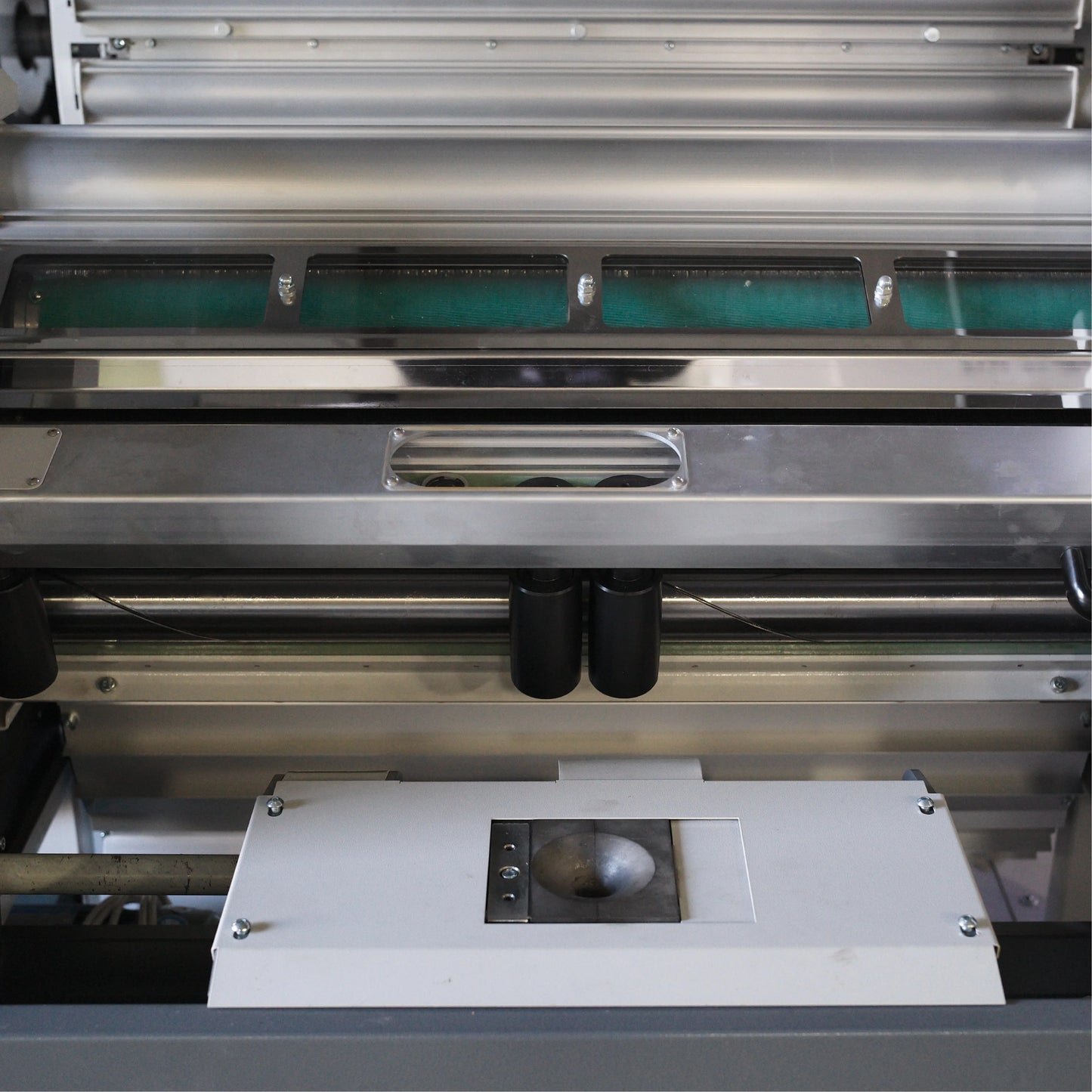

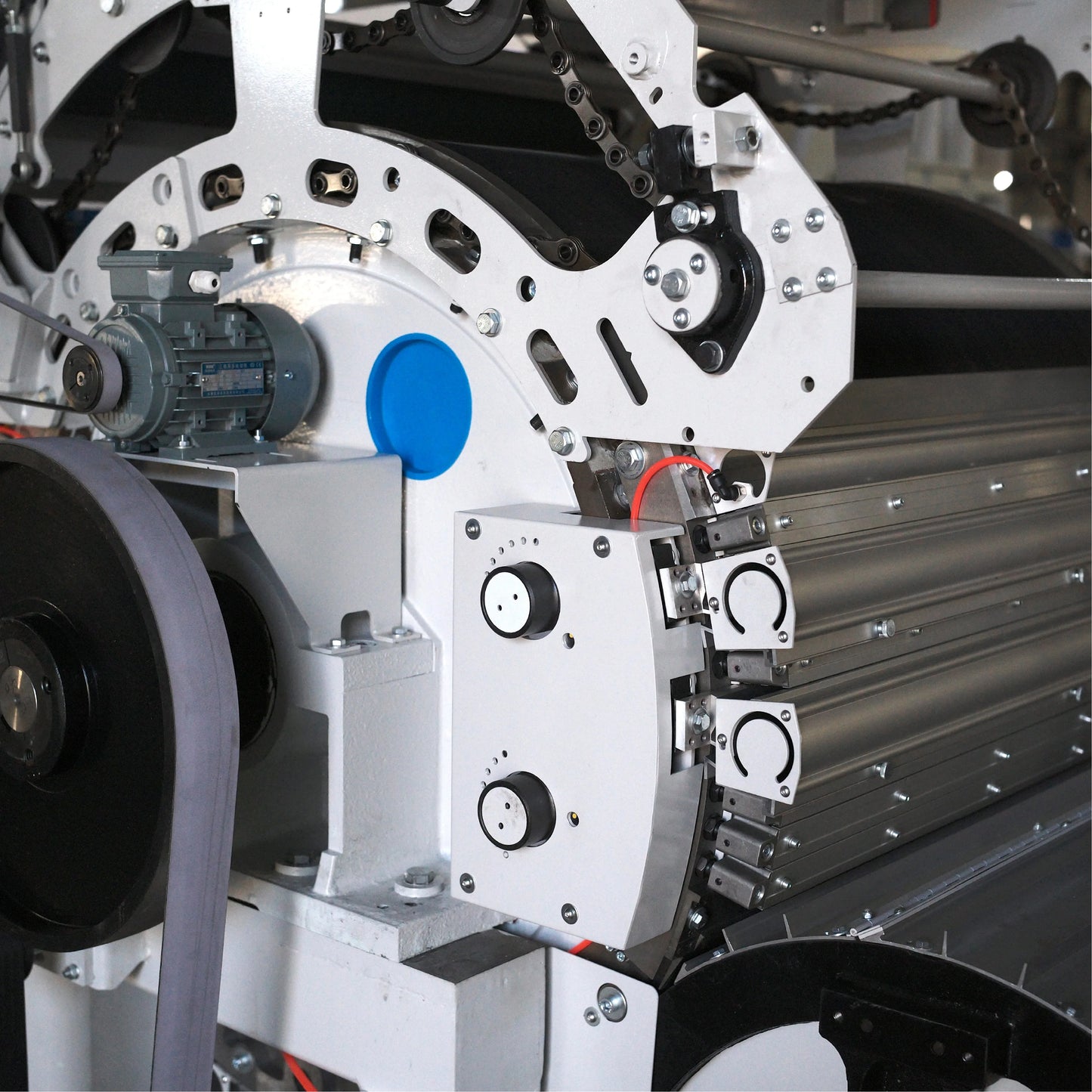

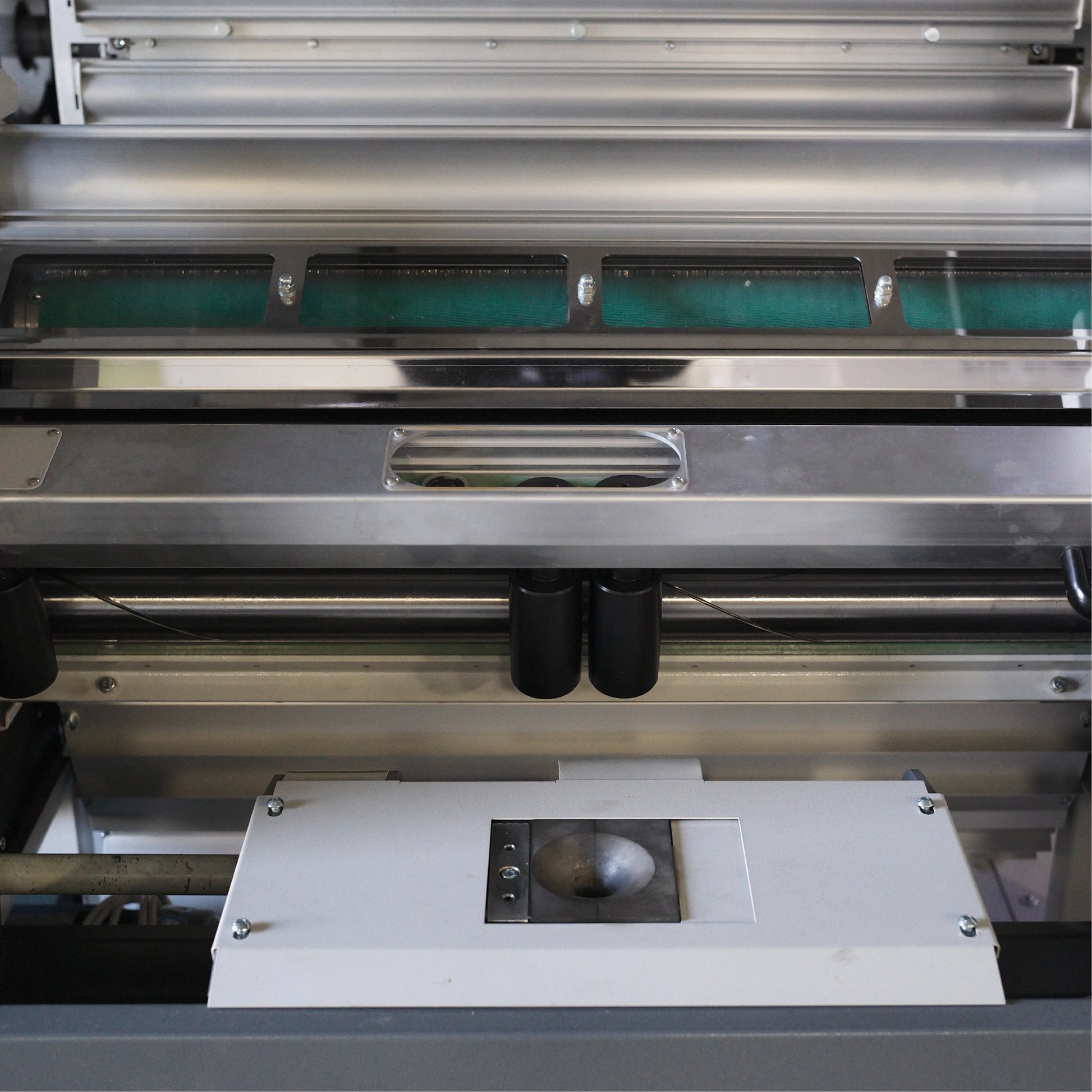

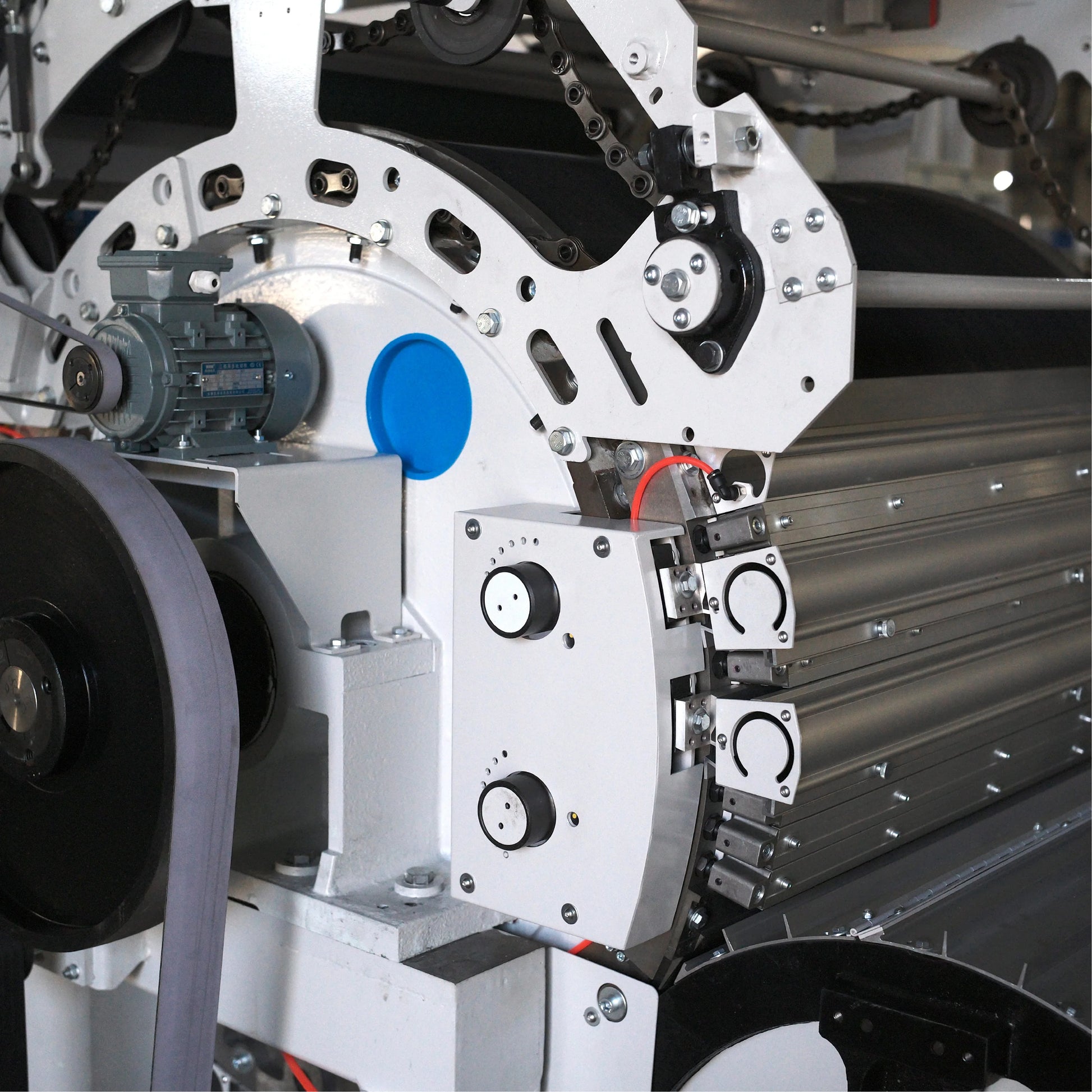

The cotton carding machine FA206B is the accurate and perfect cast iron entity cylinder and made with German resin sand technology. It is featured by netter stability without deformation to ensure precise gauge of various flats when spinning different yarn type.Rotary Flat is support by four points that is made by wear resistant material to ensure minimum flat tip height difference and extend duration.Front.rear stationery flats and web cleaner are made by aluminum alloy, good tip neatness and convenient gage adjustment to ensure fiber carding more fully and fine.

Product details

FA206B Carding machine is the accurate and perfect cast iron entity cylinder is made with German resin sand technology. It is featured by netter stability without deformation to ensure precise gauge of various flats when spinning different yarn type.Rotary Flat is support by four points that is made by wear resistant material to ensure minimum flat tip height difference and extend duration.

Front.rear stationery flats and web cleaner are made by aluminum alloy, good tip neatness and convenient gage adjustment to ensure fiber carding more fully and fine.

Web cleaner, stationer flat, cover sheet are designed in modular which can be grouped and fitted according to different material and flexible dismantled with better trash excluding efficiency.Singular licker-in is mounte. It is designed with note knife, pre-carding segment, around licker- in to efficiently exclude trash and short staple. Mote knife and dust dropping zone length can be used for adjusting noil quantity to reduce fiber loss.

Advanced Control System Monitors.

The Working Status and Running Efficiency. Safety Protections and Self-Diagnosis System. Sophisticated Suction System Provide Better Opening and Cleaning. Independent Transmission Motors Adjusted by Inverts For High Efficiency. User Friendly Graphical Interface. Easy Access to control Parameters. Smart Mechanical Design Makes maintenance An Easy Take.

Main Technical Parameters

|

Production(kg/h)

|

6 5

|

|

Delivery speed (m/min)

|

320

|

|

Sliver count (g/m)

|

3.5~6.5

|

|

Feed weight (g/m)

|

300-1000

|

|

Working width (mm)

|

1000/1250

|

|

Total draft

|

60-300

|

|

Feed roller diameter(mm)

|

100

|

|

Licker-in speed

|

180,180,250

|

|

Doffer diameter(mm)

|

706

|

|

Doffer speed(r/min)

|

4^65

|

|

Cylinder diameter(mm)

|

CD 1288

|

|

Cylinder speed( r/min)

|

340-510

|

|

No. of revolving flats(working/total)

|

30/84

|

|

Flat speed(mm/min)

|

98-370

|

|

Auxiliary carding segment

|

4 licker-in Carding segments,4 front stationary flats(Cotton),4~6(Chemical fiber); 6 rear stationery flats(Cotton),6-10(Chemical fiber)

|

|

Web cleaner

|

Rear web deaner(2),Front web cleaner(1)(Cotton)

|

|

Diameter

|

60,001,000

|

|

Can size(mm)

|

|

|

Height

|

11,001,200

|

|

Continuous suction(m3/h)

|

Air volume 4000

|

|

Air pressure(Pa)

|

-920

|

|

Compressed air requirement(kg/cm2)

|

Pressure 5~7

|

|

Compressed air consumed(m3/h)

|

0.02

|

|

Total installed power(kw)

|

11,24

|

|

Safety cover form

|

Totally-enclosed structure

|

|

Space requirement(Lx W)(mm)

|

4007 x 1980 (Coiler no included)

|

|

Approx net weight) kg)

|

7500

|

|

Option

|

USTER UQAaotoleveller

|

Parameter Comparison

|

FA206B

|

FA1213A

|

|

|

Sliver count(g/m)

|

|

|

|

3.5~6.5

|

3-7

|

|

|

Feed weight (g/m)

|

|

|

|

300-1000

|

400-1000

|

|

|

Working width(mm)

|

|

|

|

1000/1250

|

1000

|

|

|

Total draft

|

|

|

|

60-300

|

60-300

|

|

FAQ

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

Our clothing factory's logistics and transportation packaging is highly reliable. We have specially designed packaging according to equipment specifications, with strong protection and stable fixation to ensure transportation safety and ensure that the equipment arrives intact.

WhatsApp : +86 15207187668

Email:ZheyaCoLtd@outlook.com

Share