1

/

of

5

FA1211 Textile Machinery Industry Spinning Automatic Cotton Combing

FA1211 Textile Machinery Industry Spinning Automatic Cotton Combing

Regular price

R 2,823,376.83 ZAR

Regular price

Sale price

R 2,823,376.83 ZAR

Unit price

/

per

Taxes included.

Shipping calculated at checkout.

Couldn't load pickup availability

as the weight of the product exceeds the maximum weight for platform transportation, please contact me before placing an order to obtain the correct price, including the selection of shipping plans and service details.

Here is my contact information

WhatsApp : +86 15207187668 Email:ZheyaCoLtd@outlook.com

#detail_decorate_root .magic-0{vertical-align:top}#detail_decorate_root .magic-1{vertical-align:top;display:block;padding-right:4px;box-sizing:border-box;padding-left:4px}#detail_decorate_root .magic-2{vertical-align:top;padding-bottom:4px;box-sizing:border-box;padding-top:4px}#detail_decorate_root .magic-3{padding:0;margin:0;white-space:pre-wrap;font-size:14px}#detail_decorate_root .magic-4{font-size:28px}#detail_decorate_root .magic-5{font-size:24px}#detail_decorate_root .magic-7{width:750px}#detail_decorate_root .magic-8{overflow:hidden;width:750px;height:267.246835443038px;margin-top:0;margin-bottom:0;margin-left:0;margin-right:0}#detail_decorate_root .magic-9{margin-top:0;margin-left:0;width:750.0000000000001px;height:267.246835443038px}#detail_decorate_root .magic-10{border-bottom-style:solid;border-bottom-color:#53647a;font-family:Roboto;font-size:24px;color:#53647a;font-style:normal;border-bottom-width:2px;padding-top:8px;padding-bottom:4px}#detail_decorate_root .magic-11{overflow:hidden;width:750px;height:241.61392405063293px;margin-top:0;margin-bottom:0;margin-left:0;margin-right:0}#detail_decorate_root .magic-12{margin-top:0;margin-left:0;width:750px;height:241px}#detail_decorate_root .magic-13{font-size:18px}#detail_decorate_root .magic-14{font-size:16px}#detail_decorate_root .magic-15{overflow:hidden;width:750px;height:299.5253164556962px;margin-top:0;margin-bottom:0;margin-left:0;margin-right:0}#detail_decorate_root .magic-16{margin-top:0;margin-left:0;width:750px;height:299px}#detail_decorate_root .magic-17{overflow:hidden;width:750px;height:571.2816455696203px;margin-top:0;margin-bottom:0;margin-left:0;margin-right:0}#detail_decorate_root .magic-18{margin-top:0;margin-left:0;width:750.0000000000001px;height:571.2816455696203px}#detail_decorate_root .magic-19{overflow:hidden;width:750px;height:261.07594936708864px;margin-top:0;margin-bottom:0;margin-left:0;margin-right:0}#detail_decorate_root .magic-20{margin-top:0;margin-left:0;width:750px;height:261px}#detail_decorate_root .magic-21{overflow:hidden;width:750px;height:324.6835443037975px;margin-top:0;margin-bottom:0;margin-left:0;margin-right:0}#detail_decorate_root .magic-22{margin-top:0;margin-left:0;width:750.0000000000001px;height:324.6835443037975px}#detail_decorate_root .magic-23{width:446px}#detail_decorate_root .magic-24{overflow:hidden;width:446px;height:316.0193370165746px;margin-top:0;margin-bottom:0;margin-left:0;margin-right:0}#detail_decorate_root .magic-25{margin-top:0;margin-left:0;width:446px;height:316px}#detail_decorate_root .magic-26{width:300px;display:flex;flex-direction:column;margin-right:0;margin-left:4px}#detail_decorate_root .magic-27{width:300px;display:flex;flex-direction:column;margin-right:4px;margin-left:0}#detail_decorate_root .magic-28{overflow:hidden;width:446px;height:312.6914600550964px;margin-top:0;margin-bottom:0;margin-left:0;margin-right:0}#detail_decorate_root .magic-29{margin-top:0;margin-left:0;width:446px;height:312px}#detail_decorate_root .magic-30{overflow:hidden;width:446px;height:309.00550964187335px;margin-top:0;margin-bottom:0;margin-left:0;margin-right:0}#detail_decorate_root .magic-31{margin-top:0;margin-left:0;width:446px;height:309px}#detail_decorate_root .magic-32{overflow:hidden;width:446px;height:312.32320441988946px;margin-top:0;margin-bottom:0;margin-left:0;margin-right:0}#detail_decorate_root .magic-33{overflow:hidden;width:446px;height:314.78729281767954px;margin-top:0;margin-bottom:0;margin-left:0;margin-right:0}#detail_decorate_root .magic-34{margin-top:0;margin-left:0;width:446px;height:314px}#detail_decorate_root .magic-35{overflow:hidden;width:446px;height:303.6988950276243px;margin-top:0;margin-bottom:0;margin-left:0;margin-right:0}#detail_decorate_root .magic-36{margin-top:0;margin-left:0;width:446px;height:303px}#detail_decorate_root .magic-37{overflow:hidden;width:446px;height:313.55524861878456px;margin-top:0;margin-bottom:0;margin-left:0;margin-right:0}#detail_decorate_root .magic-38{margin-top:0;margin-left:0;width:446px;height:313px}#detail_decorate_root .magic-39{overflow:hidden;width:446px;height:310.4986376021798px;margin-top:0;margin-bottom:0;margin-left:0;margin-right:0}#detail_decorate_root .magic-40{margin-top:0;margin-left:0;width:446px;height:310px}#detail_decorate_root .magic-41{overflow:hidden;width:750px;height:1140.1898734177216px;margin-top:0;margin-bottom:0;margin-left:0;margin-right:0}#detail_decorate_root .magic-42{margin-top:0;margin-left:0;width:750.0000000000001px;height:1140.1898734177216px}#detail_decorate_root .magic-43{overflow:hidden;width:750px;height:1090.3481012658228px;margin-top:0;margin-bottom:0;margin-left:0;margin-right:0}#detail_decorate_root .magic-44{margin-top:0;margin-left:0;width:750.0000000000001px;height:1090.3481012658228px}#detail_decorate_root .magic-45{width:750px;border-collapse:collapse}#detail_decorate_root .magic-46{min-height:18px;padding:5px 10px;width:119px;min-height:18px;box-sizing:content-box}#detail_decorate_root .magic-47{text-align:center}#detail_decorate_root .magic-48{min-height:18px;padding:5px 10px;width:155px;min-height:18px;box-sizing:content-box}#detail_decorate_root .magic-49{min-height:18px;padding:5px 10px;width:112px;min-height:18px;box-sizing:content-box}#detail_decorate_root .magic-50{min-height:18px;padding:5px 10px;width:105px;min-height:18px;box-sizing:content-box}#detail_decorate_root .magic-51{min-height:18px;padding:5px 10px;width:152px;min-height:18px;box-sizing:content-box}#detail_decorate_root .magic-52{min-height:18px;padding:5px 10px;width:294px;min-height:18px;box-sizing:content-box}#detail_decorate_root .magic-53{display:none}#detail_decorate_root .magic-54{min-height:18px;padding:5px 10px;width:154px;min-height:18px;box-sizing:content-box}#detail_decorate_root .magic-55{display:table-cell}#detail_decorate_root .magic-56{min-height:18px;padding:5px 10px;width:411px;min-height:18px;box-sizing:content-box}#detail_decorate_root .magic-57{min-height:18px;padding:5px 10px;width:153px;min-height:18px;box-sizing:content-box}#detail_decorate_root .magic-58{color:#444;font-family:"Segoe UI"}#detail_decorate_root .magic-59{min-height:18px;padding:5px 10px;width:294px;box-sizing:content-box}#detail_decorate_root .magic-60{min-height:18px;padding:5px 10px;width:155px;box-sizing:content-box}#detail_decorate_root .magic-61{min-height:18px;padding:5px 10px;width:411px;box-sizing:content-box}#detail_decorate_root .magic-62{min-height:18px;padding:5px 10px;width:105px;box-sizing:content-box}#detail_decorate_root .magic-63{min-height:18px;padding:5px 10px;width:153px;box-sizing:content-box}#detail_decorate_root .magic-64{min-height:18px;padding:5px 10px;width:410px;box-sizing:content-box}#detail_decorate_root .magic-65{font-size:32px;font-family:inherit;font-style:inherit;font-variant-ligatures:inherit;font-variant-caps:inherit}#detail_decorate_root .magic-66{overflow:hidden;width:750px;height:305.2215189873418px;margin-top:0;margin-bottom:0;margin-left:0;margin-right:0}#detail_decorate_root .magic-67{margin-top:0;margin-left:0;width:750.0000000000001px;height:305.2215189873418px}#detail_decorate_root .magic-68{min-height:18px;padding:5px 10px;width:354px;min-height:18px;box-sizing:content-box}#detail_decorate_root .magic-69{min-height:18px;padding:5px 10px;width:350px;min-height:18px;box-sizing:content-box}#detail_decorate_root .magic-70{min-height:18px;padding:5px 10px;width:166px;min-height:18px;box-sizing:content-box}#detail_decorate_root .magic-71{min-height:18px;padding:5px 10px;width:726px;min-height:18px;box-sizing:content-box}#detail_decorate_root .magic-72{min-height:18px;padding:5px 10px;width:165px;min-height:18px;box-sizing:content-box}#detail_decorate_root .magic-73{min-height:18px;padding:5px 10px;width:354px;box-sizing:content-box}#detail_decorate_root .magic-74{min-height:18px;padding:5px 10px;width:152px;box-sizing:content-box}#detail_decorate_root .magic-75{min-height:18px;padding:5px 10px;width:350px;box-sizing:content-box}#detail_decorate_root .magic-76{min-height:18px;padding:5px 10px;width:166px;box-sizing:content-box}#detail_decorate_root .magic-77{min-height:18px;padding:5px 10px;width:726px;box-sizing:content-box}#detail_decorate_root .magic-78{min-height:18px;padding:5px 10px;width:165px;box-sizing:content-box}#detail_decorate_root .magic-79{margin-bottom:10px;line-height:0}#detail_decorate_root .magic-80{margin-bottom:0}#detail_decorate_root .magic-81{position:relative;width:100%}

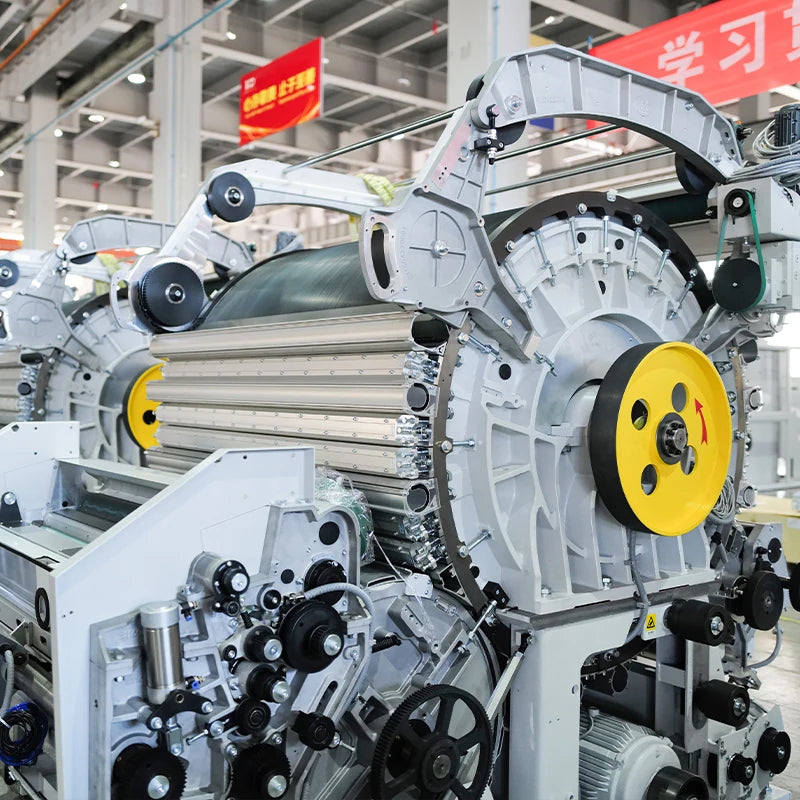

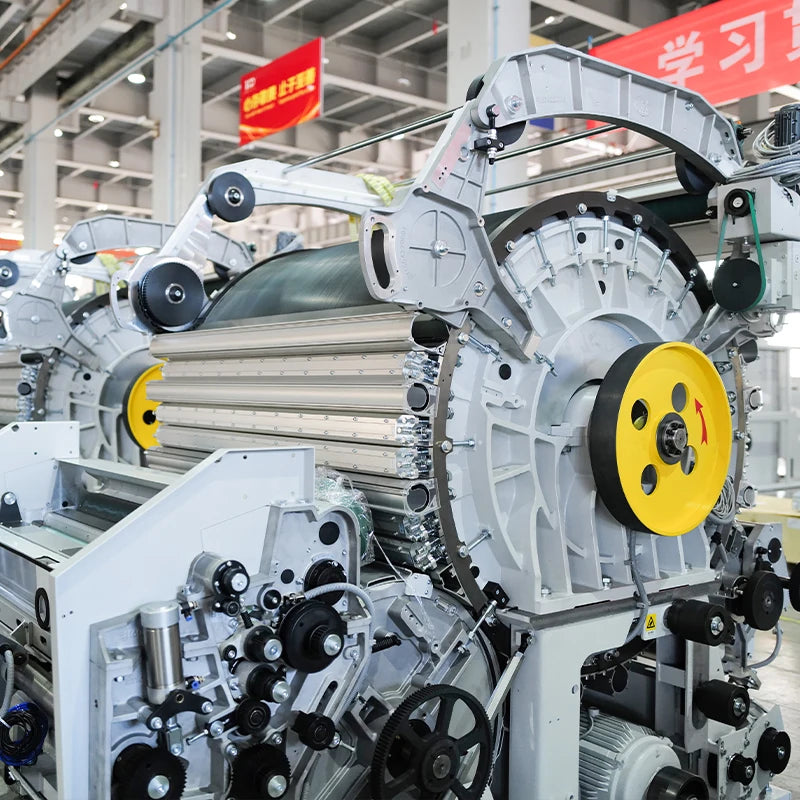

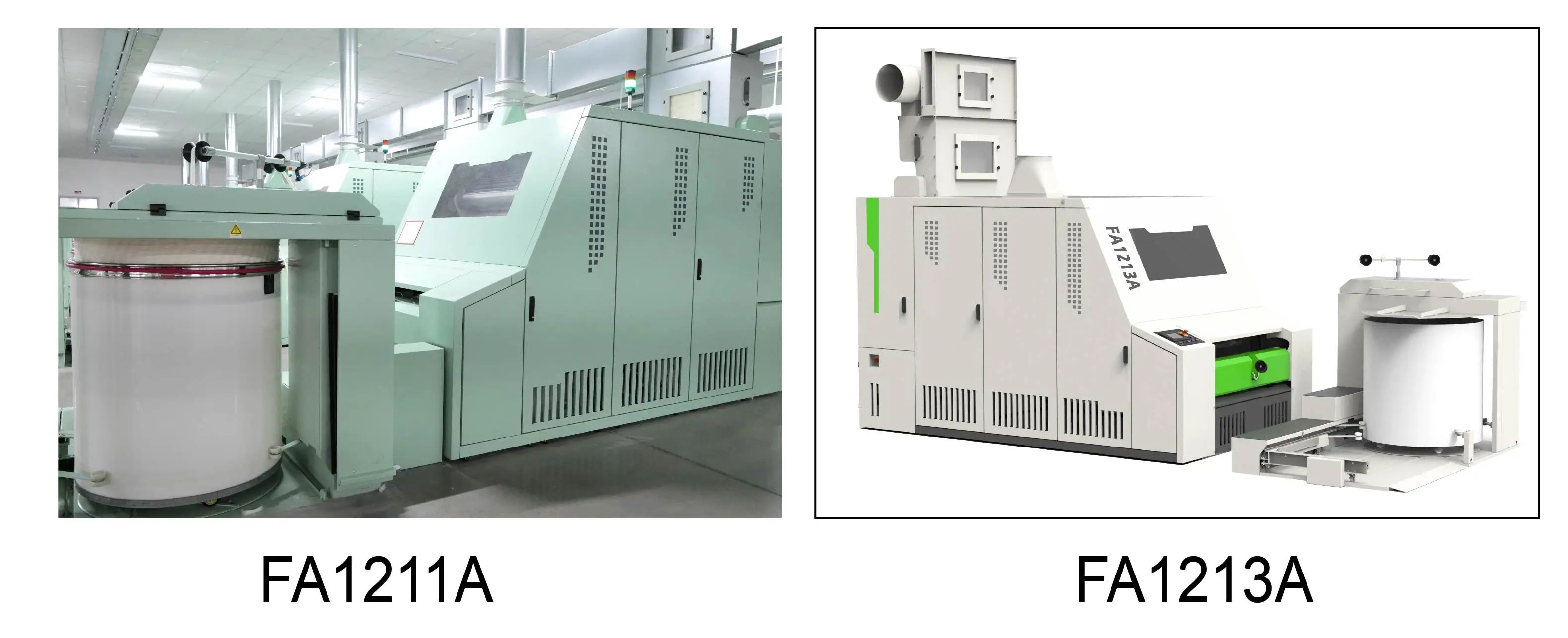

Cotton Carding Machine FA1211A FA1213A

Max. Sliver delivery speed up to 300/320(meter/min)

Max. Sliver delivery speed up to 300/320(meter/min)

Product display and advantages

Main Feature :

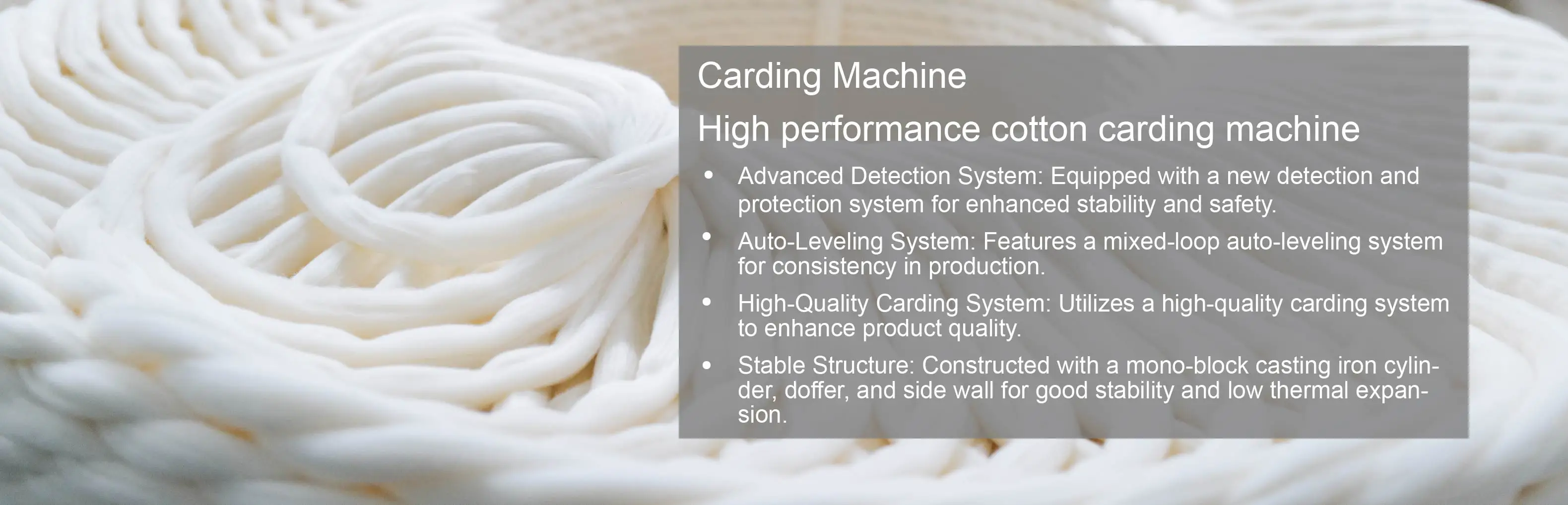

The Cotton Carding Machine FA1211A offers an optimal balance between quality and production capacity. It features a new detecting and protecting system, mixed loop auto-leveller system, and high-quality carding system. The modular design ensures easy operation and maintenance.

Product Details:

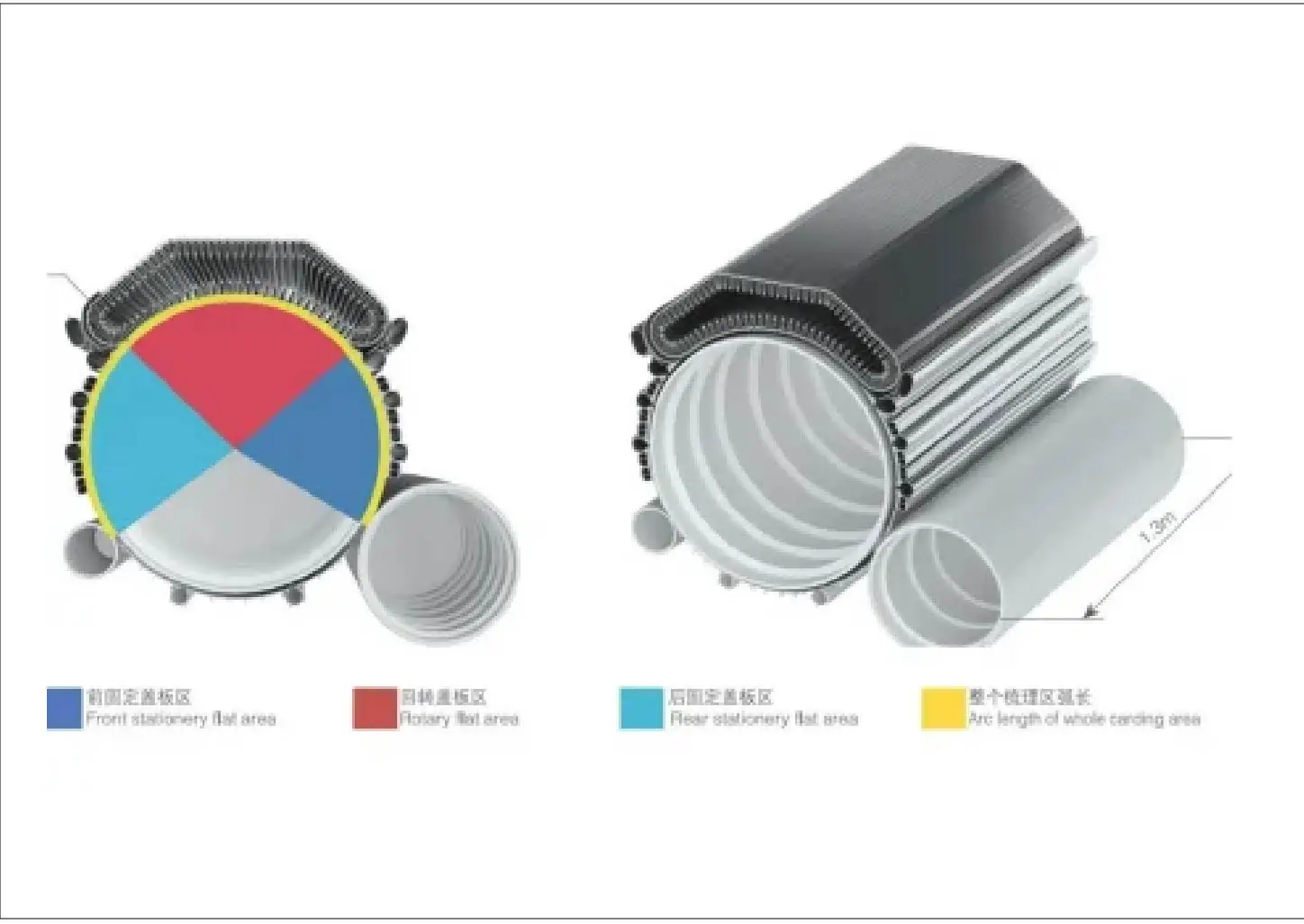

The carding arc length decides the quality. Longest carding arc lerngth of 2.8 meters ensures best quality. Mono-block casting iron cylinder, doffer and side wall ensures good stability and low thermal expansion coefficient. The carding technical gauge is stable even when machine runs at high speed, ensuring the high production. The stepped entity frame welded by steel plate is characterized by its flexible mechanism and its special processing technology, ensuring the major gauge stable and uniform.

Main Feature :

* CARDING SYSTEM WITH HIGH PRODUCTION AAND EFFICIENCY

* STABLE AND RELIABLE QUALITY GUARANTEEE

* NEW TYPE OF LICKER-IN CARDING SYSTEM

* DUST FILTERING SYSTEM

* MODULAR DESIGN-EASY OPERATION AND MAINTENANCE

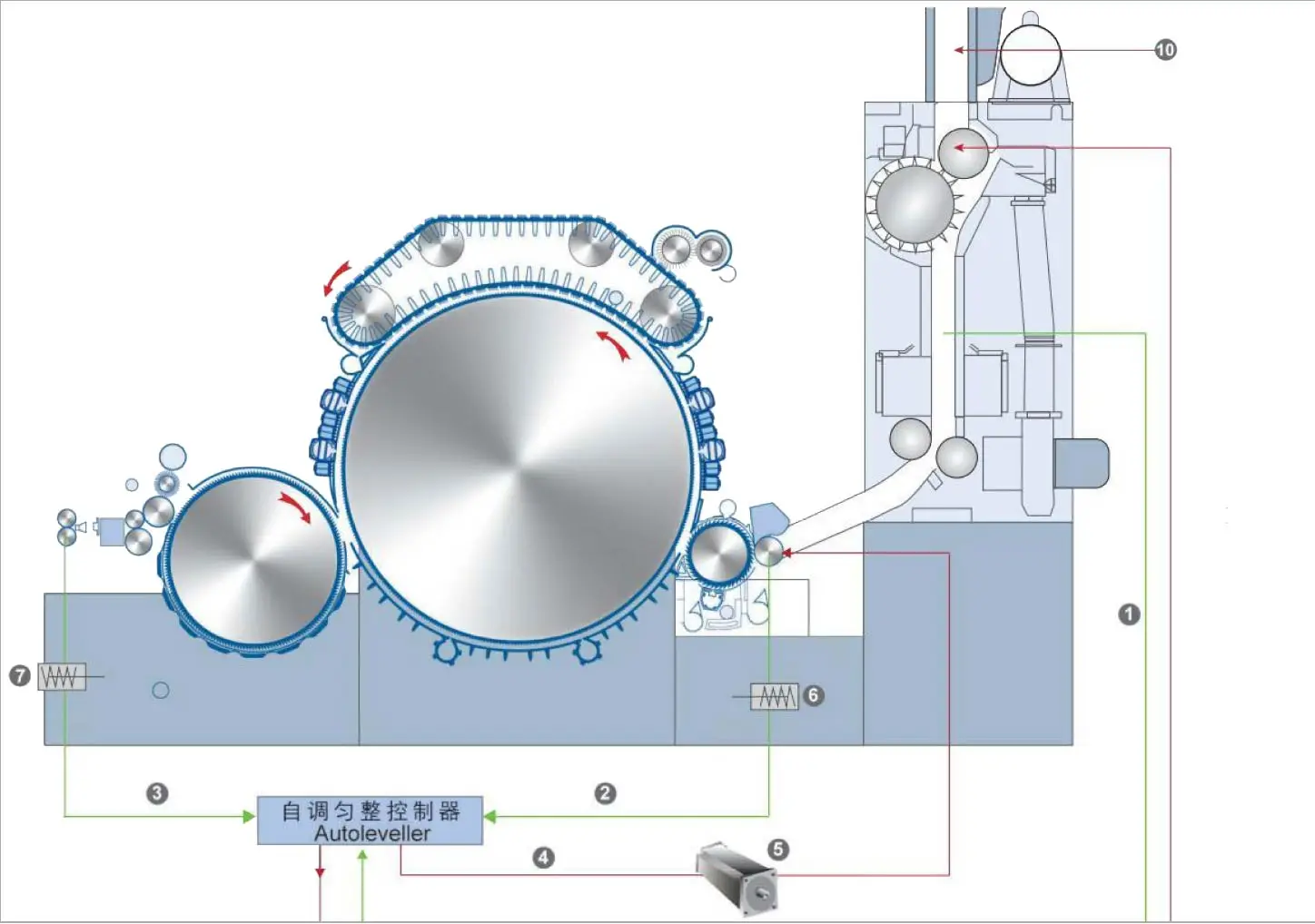

* NEW TYPE MIXED LOOP AUTO-LEVELLER SYSTEM

* NEW TYPE DETECTING AND PROTECTING :SYSTEM

* SLIVER CUTTING WITHOUT SPEED DOWN

* DISTINCTIVE 6-POINTS GAUGE

* TYPE OF CHUTE FEEDER

* STABLE AND RELIABLE QUALITY GUARANTEEE

* NEW TYPE OF LICKER-IN CARDING SYSTEM

* DUST FILTERING SYSTEM

* MODULAR DESIGN-EASY OPERATION AND MAINTENANCE

* NEW TYPE MIXED LOOP AUTO-LEVELLER SYSTEM

* NEW TYPE DETECTING AND PROTECTING :SYSTEM

* SLIVER CUTTING WITHOUT SPEED DOWN

* DISTINCTIVE 6-POINTS GAUGE

* TYPE OF CHUTE FEEDER

Product Display

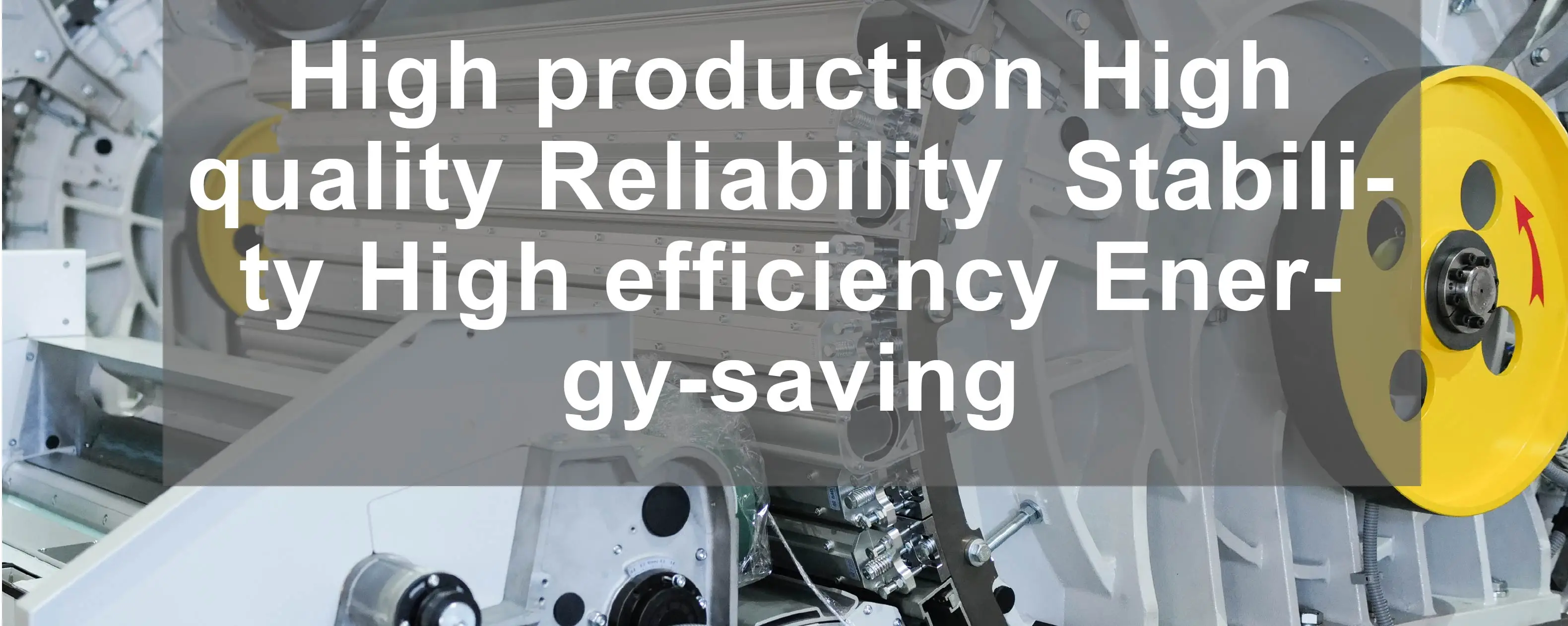

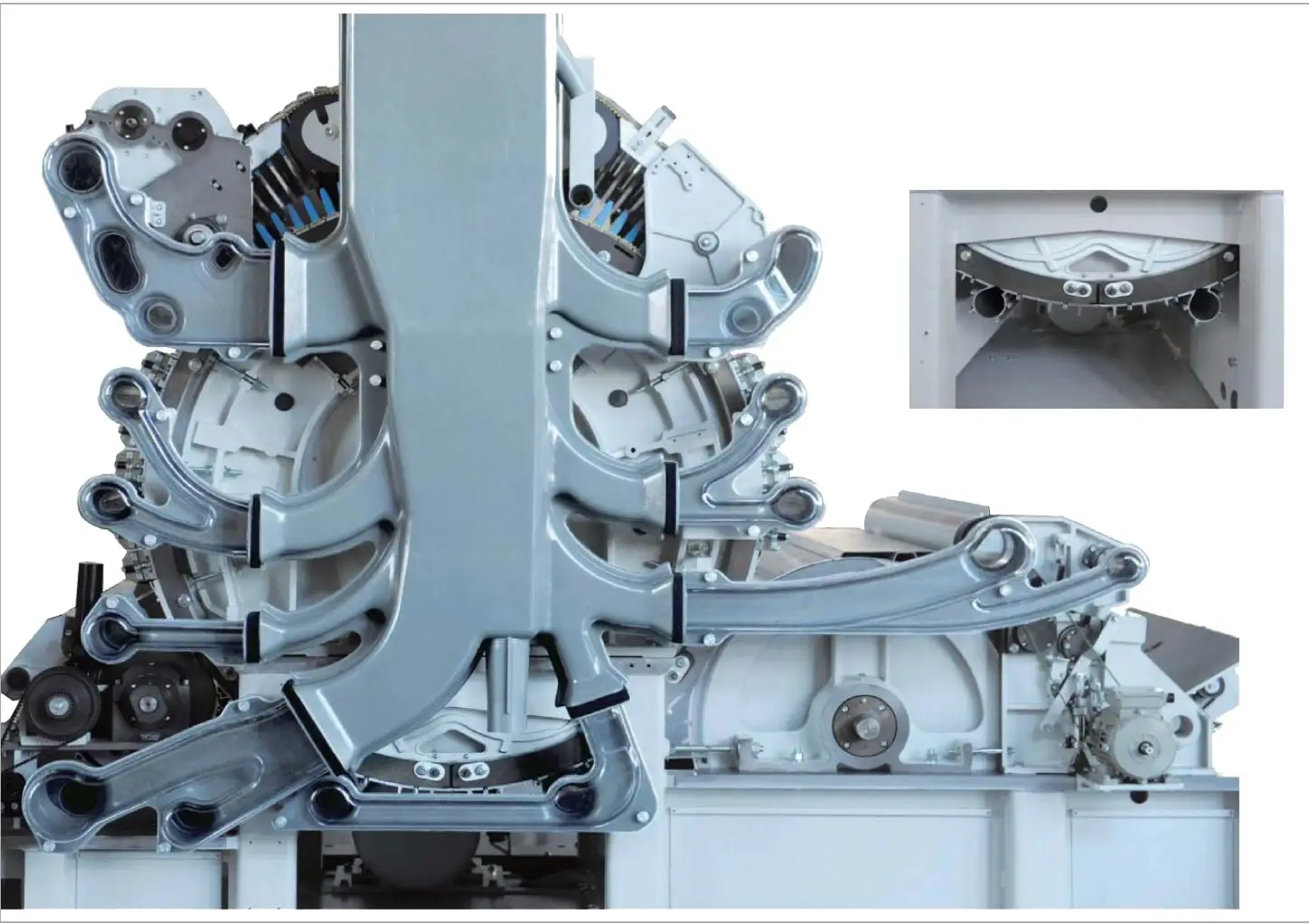

CARDING SYSTEM WITH HIGH PRODUC

TION ANND EFFICIENCY

TION ANND EFFICIENCY

The carding arc decides the quality. Longest carding arc length (of 2.8 meters ensures quality.

New type of driving method

Cylinder and licker-in adopt high torque motor, featured by stable start and reliable rotary.

Doffer is driven by inverter motor to ensure stability in lobw speed, high speed and speed conversion.

Doffer is driven by inverter motor to ensure stability in lobw speed, high speed and speed conversion.

Flat is driven by independent inverter motor for convenient speed adjustment (Optional),

Cleaning unit with high efficiency

The gauge adjustable design of the brush roller and the revolving flaits ensures the deep cleaning of the revolving flats. The optimized relative position and gauges between the brussh roller and cleaning roller ensures the timely removed of the flat cotton fly. The new type of aluminum suction hood with perfect fluid meechanics can reduce the drag and suck flat fly smoothly

NEW TYPE OF LICKER-IN CARDING

SYSTEM

SYSTEM

Licker-in is designed with two noil area whose length is adjustable outside of machine. It is designed with two sets of mote knife, pre-carding segment for efficiently removal of

trash and staple.

trash and staple.

DUST FILTERING SYSTEM

The new dust-filtering system adopts the streamline structure and is more in line with the flow kinematics, which can reduce wind resistance as well as save energy and reduce

cost.

cost.

MODULAR DESIGN-EASY OPERATION AND

IMAINTENANCE

IMAINTENANCE

Aluminum alloy rotary flat bar is made by special material,with the characteristics of good flatness, light weight, stable operation. It is guided by two tooth belts without need of other fasten parts, so it is easy for mantle, dismantle and maintenance.

MODULAR DESIGN-EASY OPERATION AND

MAINTENANCE

MAINTENANCE

The new mixed loop auto-levelling system, specially used forthe directional feeding structure, can detect the batt thick nessvariation by use of precise vertex non-contact sensor to control fiber in short term, realize the control of fiber in long term through new type of sliver weight detecting device,realize the control of chute pressure through PID, make up mixed loop control in quaternity. Fitvector motor driving system enhances drive precision and ensure stable sliver CV value.

DISTINCTIVE 6-POINTS GAUGE

Precision and stability of gauge between cylinder and rotary flat is the decisive factor for carding efficiency. Specially designed gauge adjusting method in 6 points ensures precise and stable gauge of rotary flats.

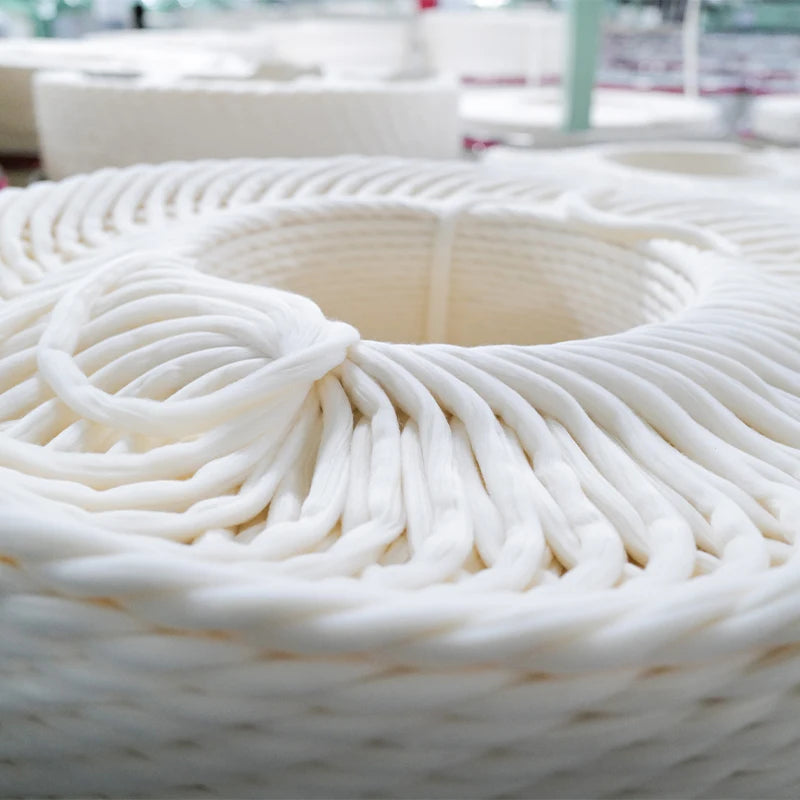

SLIVER CUTTING WITHOUT SPEED DOWN

Doffer speed needs not decrease when cutting sliver and changing can and sliver weight is stable during can- changing. The linear automatic can-changer coiler is easy to main

tain and saves space by 33% compared with rotary type. Adopting servo motor drives alone,the sliver delivery is more stable

tain and saves space by 33% compared with rotary type. Adopting servo motor drives alone,the sliver delivery is more stable

Main Technical Parameters

Type |

a |

b |

c |

d |

|||

FA1211A |

1395 |

2160 |

1980 |

3620 |

|||

Application |

Application applicable to chemical fiber,pure cotton in length from 22~76mm and other blended material |

||||||

Max. Actual output (kg/h) |

100 |

||||||

Max. Sliver delivery speed (meter/min) |

300 |

||||||

Sliver count(g/m) |

3-7 |

||||||

Feed weight(gram/meter) |

400-1000 |

||||||

Working width(mm) |

1000 |

||||||

Total draft folds |

60~300 |

||||||

Licker-in working diameter(mm) |

Ф 250 |

||||||

Doffer working diameter(mm) |

Ф 706 |

||||||

Doffer working speed(rpm) |

4.3~84 |

||||||

Cylinder working diameter(mm) |

Ф 1288 |

||||||

Cylinder working speed(rpm) |

347~477 |

||||||

Pieces of rotary(working flat/total flats |

30/84 |

||||||

Flat speed (mm/min) |

70~408 |

||||||

Continuous air suction volume(m9/hour) |

4000 |

||||||

Statistic pressure at exit(pa) |

-800 |

||||||

Compressed air pressure (kg/cm²) |

6-7 |

||||||

Compressed air consumption(m3/h) |

0.5 |

||||||

Total power installation(KW) |

11.24 |

||||||

Safety cover type |

Totally enclosed |

||||||

Land occupation (LxWxH)(mm) |

5825X2480x3555 (Ф1000) |

||||||

Machine net weight(kg) |

7200 |

||||||

Corollary chute feeder model |

FA1173B |

||||||

Type |

a |

b |

c |

d |

|||

FA1213A |

1395 |

2160 |

2240 |

3620 |

|||

Application |

Application applicable to chemical fiber,pure cotton in length from 22~76mm and other blended material |

||||||

Max. Actual output (kg/h) |

160 |

||||||

Max. Sliver delivery speed (meter/min) |

320 |

||||||

Sliver count(g/m) |

3.5~10 |

||||||

Feed weight(gram/meter) |

400~1300 |

||||||

Working width(mm) |

1280 |

||||||

Total draft folds |

38~370 |

||||||

Licker-in working diameter(mm) |

Ф 250 |

||||||

Doffer working diameter(mm) |

Ф 706 |

||||||

Doffer working speed(rpm) |

4.3~84 |

||||||

Cylinder working diameter(mm) |

Ф 1288 |

||||||

Cylinder working speed(rpm) |

347~477 |

||||||

Pieces of rotary(working flat/total flats |

30/84 |

||||||

Flat speed (mm/min) |

70~408 |

||||||

Continuous air suction volume(m9/hour) |

4500 |

||||||

Statistic pressure at exit(pa) |

-800 |

||||||

Compressed air pressure (kg/cm²) |

6-7 |

||||||

Compressed air consumption(m9/h) |

0.5 |

||||||

Total power installation(KW) |

13.9 |

||||||

Safety cover type |

Totally enclosed |

||||||

Land occupation (LxWxH)(mm) |

5825X2480x3555 (Ф1000) |

||||||

Machine net weight(kg) |

8000 |

||||||

Corollary chute feeder model |

FA1177B |

||||||

Parameter Comparison

FA1211A |

FA1213A |

|||||

Max. Actual output (kg/h) |

||||||

100 |

160 |

|||||

Max. Sliver delivery speed (meter/min) |

||||||

300 |

320 |

|||||

Sliver count(g/m) |

||||||

3-7 |

3.5~10 |

|||||

Feed weight(gram/meter) |

||||||

400-1000 |

400~1300 |

|||||

Total draft folds |

||||||

60~300 |

38~370 |

|||||

FAQ

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

Our clothing factory's logistics and transportation packaging is highly reliable. We have specially designed packaging according to equipment specifications, with strong protection and stable fixation to ensure transportation safety and ensure that the equipment arrives intact.

WhatsApp : +86 15207187668

Email:ZheyaCoLtd@outlook.com

Share