1

/

of

4

Customized Spot Or Press Welder For Auto Industry Welding Machine

Customized Spot Or Press Welder For Auto Industry Welding Machine

Regular price

R 2,782,827.15 ZAR

Regular price

Sale price

R 2,782,827.15 ZAR

Unit price

/

per

Taxes included.

Shipping calculated at checkout.

Couldn't load pickup availability

Friends, welcome to our store, you can tell me your specific product requirements, if you need other models of this product, please contact me, I will send the product link for your purchase! WhatsApp/WeChat: Aida +86 15381935847 (Reply within 10 minutes) Email: yihua.aida@gmail.com (Reply within 8 hours)

Products Description

|

Rated Capacity:

|

40KVA

|

Power Supply:

|

380V/3φ/50Hz

|

|

Max. Primary Current:

|

79A

|

Max.Short Circuit Current:

|

80KA

|

|

Max Working Pressure:

|

15000 N

|

Dimension(L*W*H):

|

1495*1069*2303MM

|

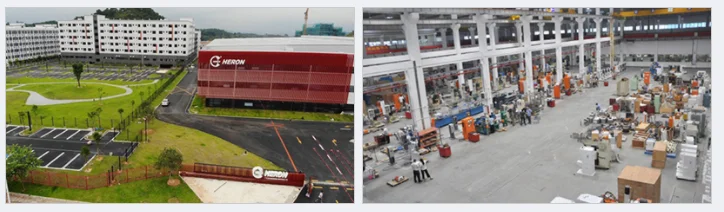

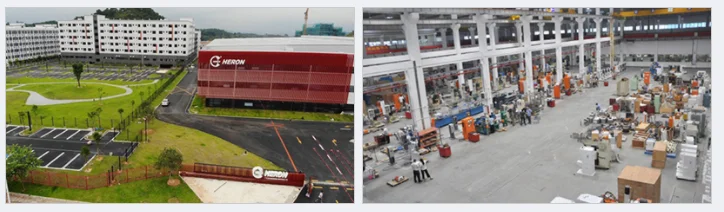

Company Profile

Heron owns over 57,000 square meters property;developed MFDC welding system, Capacitor discharge welding system, three-phase DC welding system; single phase AC welding system;offer a complete range of standard resistance welding equipments; and customize automation resistance welding production system with fixture; pursue high welding technology researching and developing all the time.

Our productions apply to different field like: car body production line, automotive part production line, refrigerator compressor welding line, silver tip with copper welding system, hardware welding; home appliance manufacturer line etc ,supplying the high tech and energy saving welding equipment and integrate the working station.

Our production lines include: press welders; manual and robotic welding guns, seam welders, bench welders; rocker arm welders,flash butt welders, multi gun auto welder with wire feeder; customized work station, clinch system with BTM Tog-L-Loc; automatic arc welding stations etc.

Our productions apply to different field like: car body production line, automotive part production line, refrigerator compressor welding line, silver tip with copper welding system, hardware welding; home appliance manufacturer line etc ,supplying the high tech and energy saving welding equipment and integrate the working station.

Our production lines include: press welders; manual and robotic welding guns, seam welders, bench welders; rocker arm welders,flash butt welders, multi gun auto welder with wire feeder; customized work station, clinch system with BTM Tog-L-Loc; automatic arc welding stations etc.

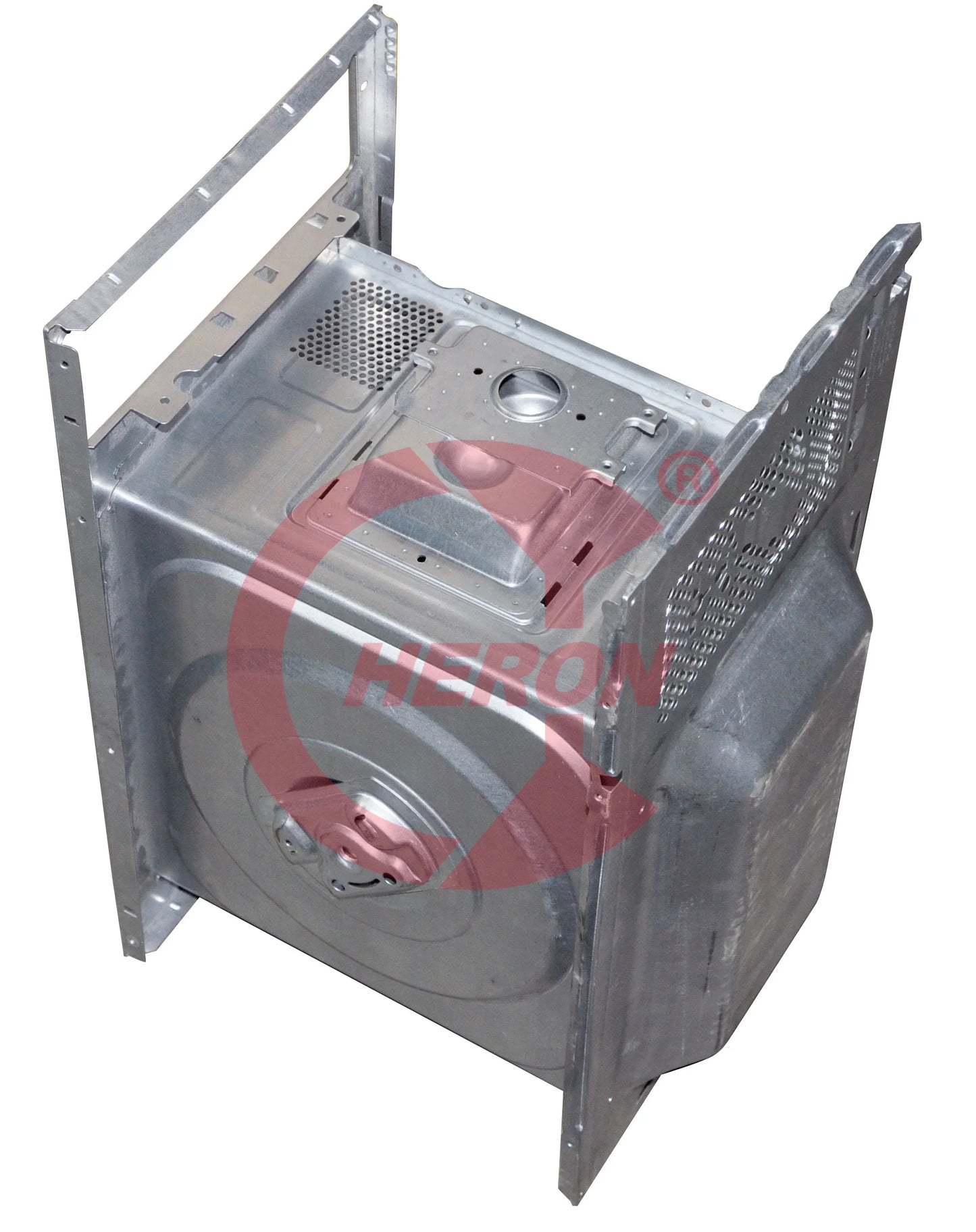

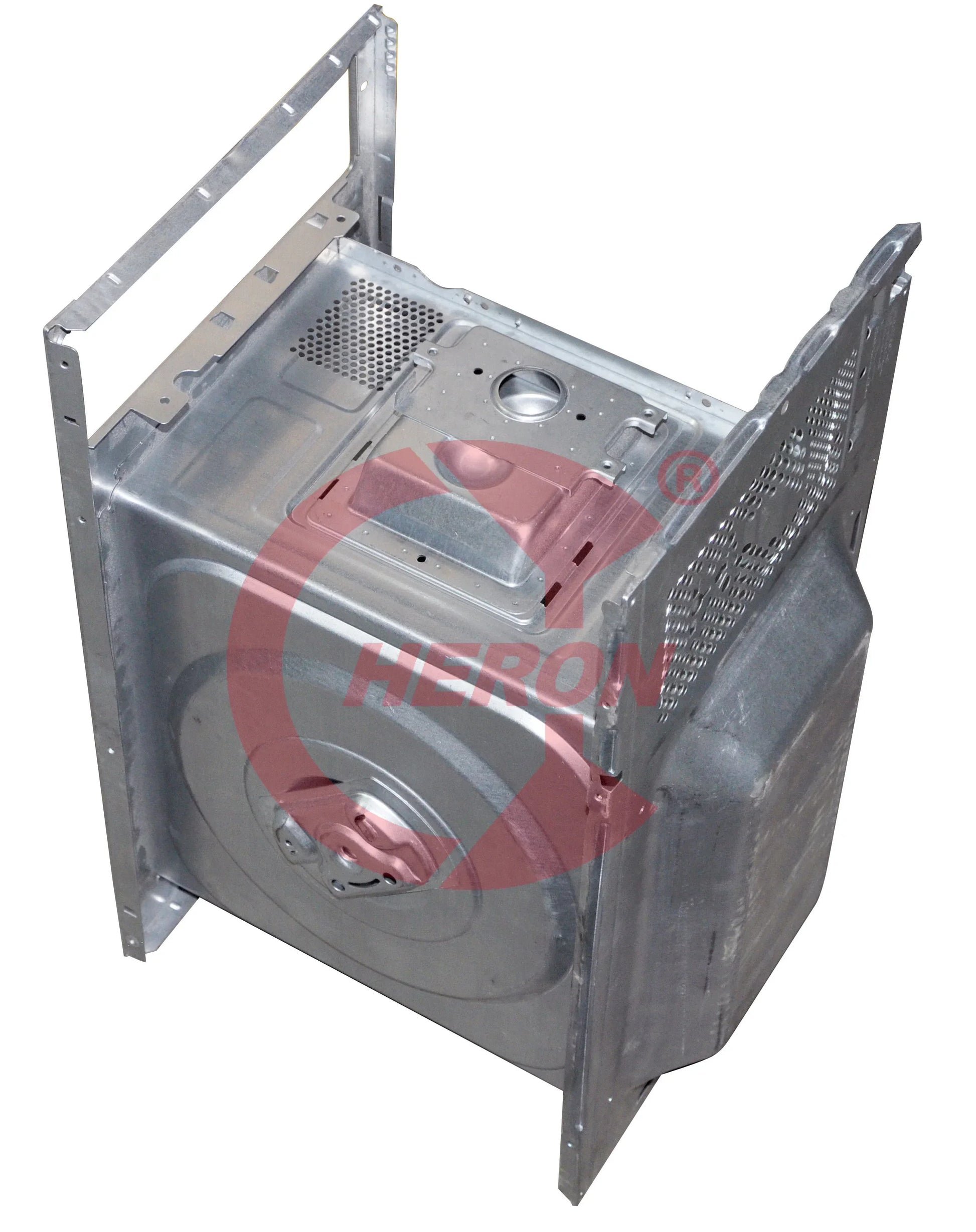

Manufacturing Process

Packaging&Delivery

Packing

Packaging Details:wooden boxes

Port:Huangpu/Guangzhou

Lead Time : 3 months after confirming drawing & receiving deposit

Port:Huangpu/Guangzhou

Lead Time : 3 months after confirming drawing & receiving deposit

Product Delivery

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

Customer Photos

FAQ

1. Q: Are you a trading company or a factory?

A: We are a manufacturing factory.

2. Q: Where is your factory located?

A: Our factory is located in Conghua district, Guangzhou of China.

3. Q: Can you customize the machine?

A: We can customize the machine according to your requirements.

4. Q: What is the MOQ?

A: According to the customer's requirements.

5. Q: What are your services during the purchase process?

A: Pre-sales: Visit the factory, Technical solutions and program design services, Proofing services, Sample testing services.

On-sales: Technical training, Installation and commissioning services.

After-sales: Free non-wearable parts, Repair service, Video technical support, Online remote guidance.

A: We are a manufacturing factory.

2. Q: Where is your factory located?

A: Our factory is located in Conghua district, Guangzhou of China.

3. Q: Can you customize the machine?

A: We can customize the machine according to your requirements.

4. Q: What is the MOQ?

A: According to the customer's requirements.

5. Q: What are your services during the purchase process?

A: Pre-sales: Visit the factory, Technical solutions and program design services, Proofing services, Sample testing services.

On-sales: Technical training, Installation and commissioning services.

After-sales: Free non-wearable parts, Repair service, Video technical support, Online remote guidance.

Share