TD-200-400 High Pressure Textile Sand Washing and Dyeing Machine

TD-200-400 High Pressure Textile Sand Washing and Dyeing Machine

Precio habitual

R 2,823,376.83 ZAR

Precio habitual

Precio de oferta

R 2,823,376.83 ZAR

Precio unitario

/

por

Impuestos incluidos.

Los gastos de envío se calculan en la pantalla de pago.

No se pudo cargar la disponibilidad de retiro

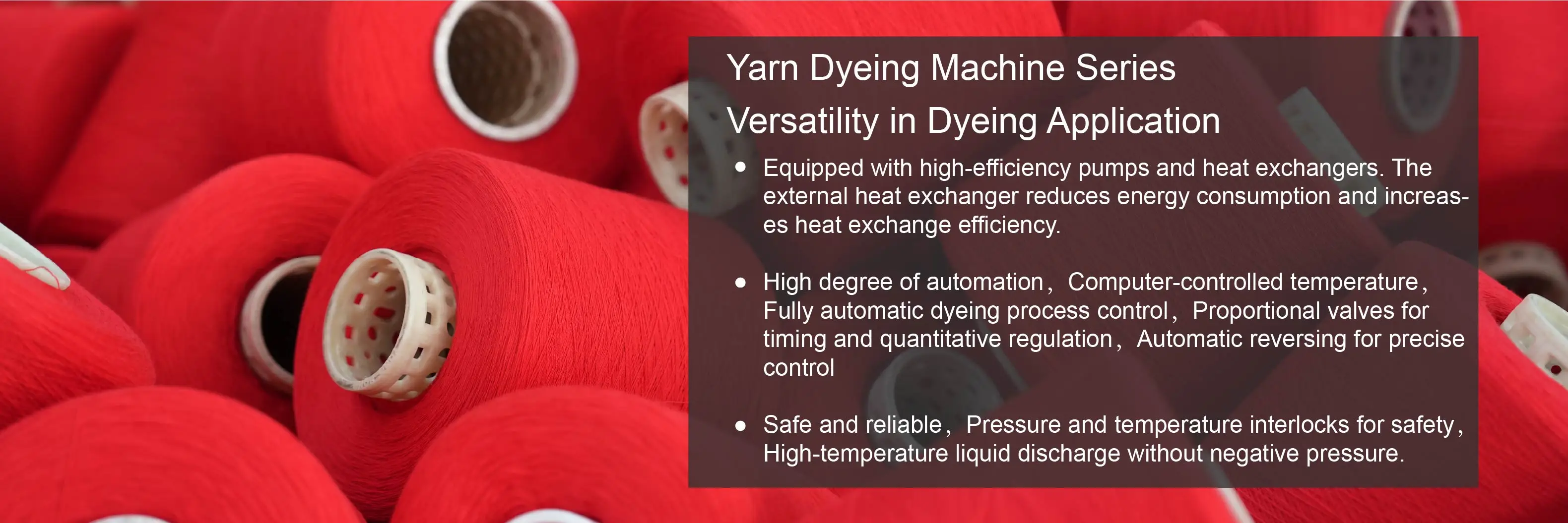

Yarn Dyeing Machine Series Yarn Dyeing Equipment Line

Product display and advantages

HIGH-TEMPERATURE, HIGH-PRESSURE DYEING MACHINE

Main Feature

•Adoption of high-efficient balanced circulation pump and reversing heat exchanger integrating, high efficiency, energy

saving andlong letime. The equipment can meet the demand of dyeing various kinds of cheeses:

•Equipped with reverse mechanism to realze forward and backward circulation of dye liquor according to technological

requirement

•Adopting pressurized form and air cushion form (or pressurized by using auxiliary feed pump);

•Nick sealing and self-sealing by intemal pressure

•High automation, computer temperature control, full-automatic control of dyeing process including water in, water out,

temperature rise, thermal insulation,temperature drop, washing.etc

•Timing and quantitative regulation of yam feed and stream input by,proportional control valve

•Fitted with auxillary preheating cylinder for reducing dyeing cycle, increasing efficiency and optimizing dyeing result

•Pressure material:Durable SUS321 (or 316L);

•Safety interlock for cover using pressure controller and temperature controller to control locking pin on the cylinder opening. The cover can be opened only when pressure is "0" and temperature below 80°C;

•High temperature liquor discharge system with no instantaneous negative pressure produced providing safer liquor drainage, apparatus creates features of compact structure, low bath ratio, short piping

•External heat exchanger capable of increasing heat exichange efficiency and reducing energy consumption

•Adoption of high-efficient balanced circulation pump and reversing heat exchanger integrating, high efficiency, energy

saving andlong letime. The equipment can meet the demand of dyeing various kinds of cheeses:

•Equipped with reverse mechanism to realze forward and backward circulation of dye liquor according to technological

requirement

•Adopting pressurized form and air cushion form (or pressurized by using auxiliary feed pump);

•Nick sealing and self-sealing by intemal pressure

•High automation, computer temperature control, full-automatic control of dyeing process including water in, water out,

temperature rise, thermal insulation,temperature drop, washing.etc

•Timing and quantitative regulation of yam feed and stream input by,proportional control valve

•Fitted with auxillary preheating cylinder for reducing dyeing cycle, increasing efficiency and optimizing dyeing result

•Pressure material:Durable SUS321 (or 316L);

•Safety interlock for cover using pressure controller and temperature controller to control locking pin on the cylinder opening. The cover can be opened only when pressure is "0" and temperature below 80°C;

•High temperature liquor discharge system with no instantaneous negative pressure produced providing safer liquor drainage, apparatus creates features of compact structure, low bath ratio, short piping

•External heat exchanger capable of increasing heat exichange efficiency and reducing energy consumption

HIGH-TEMPERATURE, HIGH-PRESSURE DYEING MACHINE

Main Feature

•Adoption of high-efficient balanced circulation pump and reversing heBat exchanger integrating apparatus creates features of compact structure. Has the high efficiency, the province energy, the life to be long. Caan meet the needs which each kind of pony roll yarn dyes.

•Equipped with reverse mechanism to180°C realize forward arnd back ward circulation of dye liquor according to technologcal requirement

•Adopting pressurized form and air cushion form (or pressurized by using auxiliary feed pump);

•Nick sealing and self-sealing by internal pressure:

•High automation, computer temperature control, full-automatiocontrol of dyeing process including water in,water out, temperature rise, thermal insulation, temperature drop, washing, etc;

•Timing and quantitative regulation of yarn feed and stream input by proportional control valve; Proportion control valve

design varies depending on our customers' choice.

•Main pump motor drive for frequency inverter control allows limitless flow control to save energy consumption on starting and load-relievingoperation.

•Pressure material: Durable SUS321 (or 316L);Our product desiggn varies depending on our customers' choice. Our products are made of conrosion resistant steel grades and have a long service life.

•Safety intertock for cover using pressure controller and tempperature controller to control locking pin on the cylinder opening. The oover can be opened only when pressure is "0" and temperature below 80°C;

•High temperature liquor discharge system with no instantaneous negative pressure produced providing safer liquor drainage:

•The outdoors-installed heat exchanger is designed for adirect connection with the main pump, thus giving a compact

arrangement. This design allows higher heat efficiency and lower energy cornsumption,and low bath ratio, short piping.

•Free choice of components and high-speed screen frame unloading allows lower labor intensity.

•Adoption of high-efficient balanced circulation pump and reversing heBat exchanger integrating apparatus creates features of compact structure. Has the high efficiency, the province energy, the life to be long. Caan meet the needs which each kind of pony roll yarn dyes.

•Equipped with reverse mechanism to180°C realize forward arnd back ward circulation of dye liquor according to technologcal requirement

•Adopting pressurized form and air cushion form (or pressurized by using auxiliary feed pump);

•Nick sealing and self-sealing by internal pressure:

•High automation, computer temperature control, full-automatiocontrol of dyeing process including water in,water out, temperature rise, thermal insulation, temperature drop, washing, etc;

•Timing and quantitative regulation of yarn feed and stream input by proportional control valve; Proportion control valve

design varies depending on our customers' choice.

•Main pump motor drive for frequency inverter control allows limitless flow control to save energy consumption on starting and load-relievingoperation.

•Pressure material: Durable SUS321 (or 316L);Our product desiggn varies depending on our customers' choice. Our products are made of conrosion resistant steel grades and have a long service life.

•Safety intertock for cover using pressure controller and tempperature controller to control locking pin on the cylinder opening. The oover can be opened only when pressure is "0" and temperature below 80°C;

•High temperature liquor discharge system with no instantaneous negative pressure produced providing safer liquor drainage:

•The outdoors-installed heat exchanger is designed for adirect connection with the main pump, thus giving a compact

arrangement. This design allows higher heat efficiency and lower energy cornsumption,and low bath ratio, short piping.

•Free choice of components and high-speed screen frame unloading allows lower labor intensity.

HIGH TEMPERATURE CONE DYEING MACHINE

Main Feature

•TD241J Model ECO High Temperature Cone Dyeing Machine is suitble for dyeing and bleaching all kinds of nature,chemical fiber and it's blended yarn, such as cotton, polyester cottoon blend,polyester, acrylic, just etc.

•Extremely low liqor ratio of 1:3.5, it can save a lot of additivee,water, electrcity and steam, and shorten the dyeing time.

•New designed spring heat exchanger, it can fully utilize the heat, so that improve the heating speed and its useful life.

•Single cycle dyeing method, it saves the exchange time of pump reverse and inverse circulation.

•Special designed spindle, it reduce the dyeing liquor volume inside the spindle,so that reduce the liqor ratio.

•High lift and big flow centrifugal pump, stepless controlled by inverter, it can Intelligent automatic regulation the yarn inside and outside pressure difference, enform the uniform dyeing for rove and fine yarn, reduce the yarn damage and emergy consumption.

•Advance double dosing tank, shorten the processtime,improve the working effciency.

•TD241J Model ECO High Temperature Cone Dyeing Machine is suitble for dyeing and bleaching all kinds of nature,chemical fiber and it's blended yarn, such as cotton, polyester cottoon blend,polyester, acrylic, just etc.

•Extremely low liqor ratio of 1:3.5, it can save a lot of additivee,water, electrcity and steam, and shorten the dyeing time.

•New designed spring heat exchanger, it can fully utilize the heat, so that improve the heating speed and its useful life.

•Single cycle dyeing method, it saves the exchange time of pump reverse and inverse circulation.

•Special designed spindle, it reduce the dyeing liquor volume inside the spindle,so that reduce the liqor ratio.

•High lift and big flow centrifugal pump, stepless controlled by inverter, it can Intelligent automatic regulation the yarn inside and outside pressure difference, enform the uniform dyeing for rove and fine yarn, reduce the yarn damage and emergy consumption.

•Advance double dosing tank, shorten the processtime,improve the working effciency.

HIGH TEMPERATURE HIGH PRESSURE DYEING MACHINE

Main Feature

Bleaching, scouring, dyeing, rinsing and post-treatmentof hank,thread and tape, embroidery thread of various natural and

syntthetic fibers as well as pure silk

Bleaching, scouring, dyeing, rinsing and post-treatmentof hank,thread and tape, embroidery thread of various natural and

syntthetic fibers as well as pure silk

Standard features

•High erostion proof stainless steel materials made for the machine body

•Durable nozzel pipe and hold set

•Yarn pole transmittion set with high efficiency

•Pumping of great flowage and low height of lift

•Stirring, heating,circumflence,clansing,and feeding set in the color bucket

•Outlay heat exchangeer of high efficiency

•Water level Indicator

•Tools assist to entry and outlet of yarn and cleaning nozzel piipes

•Flow adjust set

Accessories

•Full auto or semi-auto PC control system

•Frequency conversion control of master pump motor

•Rated material feeding system

•The 2nd water,and the 2nd disdischarge.

•Full auo control of color bucket

•High erostion proof stainless steel materials made for the machine body

•Durable nozzel pipe and hold set

•Yarn pole transmittion set with high efficiency

•Pumping of great flowage and low height of lift

•Stirring, heating,circumflence,clansing,and feeding set in the color bucket

•Outlay heat exchangeer of high efficiency

•Water level Indicator

•Tools assist to entry and outlet of yarn and cleaning nozzel piipes

•Flow adjust set

Accessories

•Full auto or semi-auto PC control system

•Frequency conversion control of master pump motor

•Rated material feeding system

•The 2nd water,and the 2nd disdischarge.

•Full auo control of color bucket

JET-TYPE SKEIN DYEING MACHINE

Main Feature

Jet-type Skein Dyeing Machine is most suitable for dyeing of single filament, single-strand fine yarn, man-made filament silk and mercerized cotton yarn, etc. The novel barrage-spilling type yarn jet dyeing tubes can ensure evenness of dyeing without raising defects and yarn seizure or knot forming as well as easily rewinding of cyed yarn. The water pump specially designed with low head and great flow and the flow regulator specially equipped allow reguulation of quantity of water at will according to quantity of yarn being dyedand its count.

Standard features

•The body of machine introduces stainless steel with a good quality too resi sterosion.

•The adjutage adopts the be made from stainless steel with a great cuality to resist erosion.

•It is a mingling water stainless steel pump with great perkormaance, It has sigillating fabrication by engine also.

•The barrel of adding material has the churning, heating, circulating,and cleaning installations.

•The reliable PLC control instrument of procedure.

•The display of waten line

•The implements are convenient to add yams, to take out yarns,t ocllean the jet pipe.

•The visible window have beautiful appearances and security

Technique data of accessories

•The highest work temperature: 98°C

•The rising temperature speed: about 5 C/minute(according to the steamy pressure 6kg/cmÇ)

•The falling temperature speed: about 4°C/minute(according to the refrigerant pressure 3kg/cmÇ)

Jet-type Skein Dyeing Machine is most suitable for dyeing of single filament, single-strand fine yarn, man-made filament silk and mercerized cotton yarn, etc. The novel barrage-spilling type yarn jet dyeing tubes can ensure evenness of dyeing without raising defects and yarn seizure or knot forming as well as easily rewinding of cyed yarn. The water pump specially designed with low head and great flow and the flow regulator specially equipped allow reguulation of quantity of water at will according to quantity of yarn being dyedand its count.

Standard features

•The body of machine introduces stainless steel with a good quality too resi sterosion.

•The adjutage adopts the be made from stainless steel with a great cuality to resist erosion.

•It is a mingling water stainless steel pump with great perkormaance, It has sigillating fabrication by engine also.

•The barrel of adding material has the churning, heating, circulating,and cleaning installations.

•The reliable PLC control instrument of procedure.

•The display of waten line

•The implements are convenient to add yams, to take out yarns,t ocllean the jet pipe.

•The visible window have beautiful appearances and security

Technique data of accessories

•The highest work temperature: 98°C

•The rising temperature speed: about 5 C/minute(according to the steamy pressure 6kg/cmÇ)

•The falling temperature speed: about 4°C/minute(according to the refrigerant pressure 3kg/cmÇ)

HANK YARN DYEING MACHINE

Main Feature :

•It is suitable for dealing with cotton flax, wool, man-made haairs terylene and blending twisted yarm ahead and later. When model Y is packed with yarns, it could make several processes of dyeing finished, such as swelling, refining, bleaching, dyeing, and pliability etc.

•The distance between one and another yarn bar is from 426 to 855 millimeters. So it is suitable for dyeing different hank

yams.

•It is equipped with precise and reversing controller to ensuure that inside of hank yarns could be averagely dyed by changing automation circulation direction of dying.

•It is equipped with precise and reversing controller to ensuure that inside of hank yarns could be averagely dyed by changing automation circulation direction of dying.

•Circulation water pump is well designed to fit for dyeing crafts of different kinds of hank yarns with changes in speed by

much moree leather belt wheels of degrees.

Standard features

•The body of machine and other parts getting in touch with dyye are made of excellenl stainless steel,which has high erosion-resisting ability.

•High-efficiency axial-flow pump made of stainless steel is eduipped with sealed mechanical device.

•Be equipped with two sets.

•Diversion block makes dyes circulation inside well-distributed

•Be equipped with material adding pumps which are made ofexcellent stainless steels.(excluding those models which under Y20)

•The material adding vat is equipped with, chum-dasher, adding materials,oppo site washing back and forth and cleaning

devices (device urder Y-200 don't need to churn-dasher)

•Safe and convenient device getting samples.

Accessories

•Rising curve is controlled by semi-automation computer.

•Fully auto control of color bucket.

•The main pump uses frequency conversion control.

•Material adding pumps and barrels are used in those models under Y20.

•Rated material feeding system.

•Conveyance trolley and yarn hang box.

Technique data of accessories

•The highest work temperature: 98°C

•Rising rate of temperature: About 30minutes ranging form 20°Cto 98°C(according to the steamy pressure 6kg/cmÇ).

•Falling rate of temperature: About 10minutes ranging form 98°Cto 80°C(according to the steamy pressure 3kg/cmÇ).

•It is suitable for dealing with cotton flax, wool, man-made haairs terylene and blending twisted yarm ahead and later. When model Y is packed with yarns, it could make several processes of dyeing finished, such as swelling, refining, bleaching, dyeing, and pliability etc.

•The distance between one and another yarn bar is from 426 to 855 millimeters. So it is suitable for dyeing different hank

yams.

•It is equipped with precise and reversing controller to ensuure that inside of hank yarns could be averagely dyed by changing automation circulation direction of dying.

•It is equipped with precise and reversing controller to ensuure that inside of hank yarns could be averagely dyed by changing automation circulation direction of dying.

•Circulation water pump is well designed to fit for dyeing crafts of different kinds of hank yarns with changes in speed by

much moree leather belt wheels of degrees.

Standard features

•The body of machine and other parts getting in touch with dyye are made of excellenl stainless steel,which has high erosion-resisting ability.

•High-efficiency axial-flow pump made of stainless steel is eduipped with sealed mechanical device.

•Be equipped with two sets.

•Diversion block makes dyes circulation inside well-distributed

•Be equipped with material adding pumps which are made ofexcellent stainless steels.(excluding those models which under Y20)

•The material adding vat is equipped with, chum-dasher, adding materials,oppo site washing back and forth and cleaning

devices (device urder Y-200 don't need to churn-dasher)

•Safe and convenient device getting samples.

Accessories

•Rising curve is controlled by semi-automation computer.

•Fully auto control of color bucket.

•The main pump uses frequency conversion control.

•Material adding pumps and barrels are used in those models under Y20.

•Rated material feeding system.

•Conveyance trolley and yarn hang box.

Technique data of accessories

•The highest work temperature: 98°C

•Rising rate of temperature: About 30minutes ranging form 20°Cto 98°C(according to the steamy pressure 6kg/cmÇ).

•Falling rate of temperature: About 10minutes ranging form 98°Cto 80°C(according to the steamy pressure 3kg/cmÇ).

HIGH-TEMPERATURE HIGH PRESSUIRE SAND

WASH DYEING MACHINE

Product use :

The machine is the desire bleaching and dyeing equipment with wide-range adaptability. It is applied for high-temperature or nprmal temperature dyeing and finishing knitted fabrics of wool, polyyester,acrylic fiber, cotton, artificial silk, etc (e.g.-clothes, socks,towelss, slip coverfabric, tapes,etc).

Product Features

TD-200-400 Series High-temperature, High-pressure Dyeirng Machines was newly developed by our company itself in

2006.With integration of bleaching,dyeing and washing into one and use of direct and indirect heating devices the machines can perform stable,safe and reliable operation.lts highly automatic control of programmable dyeing process from water in, startup heating-Up,heat-retaining, heating-down, washing,water discharge, alarming.end of process,etc,and precise automatic reversing functicon ensure fabric in dyeing beck to be completely turned over, thereby obtaining a leveldyeing effect. In addition it has the advartages of conservation of dye additives, water and energy as wvell as environmental protection.

Product Features

TD-200-400 Series High-temperature, High-pressure Dyeirng Machines was newly developed by our company itself in

2006.With integration of bleaching,dyeing and washing into one and use of direct and indirect heating devices the machines can perform stable,safe and reliable operation.lts highly automatic control of programmable dyeing process from water in, startup heating-Up,heat-retaining, heating-down, washing,water discharge, alarming.end of process,etc,and precise automatic reversing functicon ensure fabric in dyeing beck to be completely turned over, thereby obtaining a leveldyeing effect. In addition it has the advartages of conservation of dye additives, water and energy as wvell as environmental protection.

Main Technical Parameters

|

TD241C

|

|

|

|

|

||||

|

Type

|

Gauze layer

|

Pony roll gauze quantity

|

Biggest load capacity

|

Pump output

|

||||

|

TD241C-43

|

3

|

12

|

12

|

5.5

|

||||

|

TD241C-43

|

6

|

24

|

24

|

5.5

|

||||

|

TD241C-53

|

|

36

|

36

|

7.5

|

||||

|

TD241C-70

|

|

54

|

54

|

11

|

||||

|

TD241C-85

|

|

108

|

108

|

15

|

||||

|

TD241C-90

|

|

114

|

114

|

15

|

||||

|

TD241C-105

|

|

144

|

144

|

18.5

|

||||

|

TD241C-120

|

|

216

|

216

|

22

|

||||

|

TD241C-145

|

|

324

|

324

|

30

|

||||

|

TD241C-166

|

|

414

|

414

|

37

|

||||

|

TD241C-186

|

|

540

|

540

|

45

|

||||

|

TD241C-43

|

8

|

32

|

32

|

7.5

|

||||

|

TD241C-53

|

|

48

|

48

|

11

|

||||

|

TD241C-70

|

9

|

81

|

81

|

15

|

||||

|

TD241C-85

|

|

162

|

162

|

18.5

|

||||

|

TD241C-90

|

|

171

|

171

|

22

|

||||

|

TD241C-105

|

|

216

|

216

|

22

|

||||

|

TD241C-120

|

|

324

|

324

|

30

|

||||

|

TD241C-145

|

|

486

|

486

|

45

|

||||

|

TD241C-166

|

|

621

|

621

|

55

|

||||

|

TD241C-186

|

|

810

|

810

|

75

|

||||

|

TD241C-200

|

|

972

|

972

|

90

|

||||

|

TD241C-90

|

12

|

228

|

228

|

30

|

||||

|

TD241C-105

|

|

288

|

288

|

37

|

||||

|

TD241C-120

|

|

432

|

432

|

45

|

||||

|

TD241C-145

|

|

648

|

648

|

55

|

||||

|

TD241C-166

|

|

828

|

828

|

90

|

||||

|

TD241C-186

|

|

1080

|

1080

|

110

|

||||

|

TD241C-200

|

|

1296

|

1296

|

132

|

||||

|

TD241C-226

|

|

1608

|

1608

|

160

|

||||

FAQ

(1) Q: Why Choose Our Company? A: History: TONGDA Textile Machinery Group was establish in 1952. Now have more than 65 years old history. Main Products: TONGDA Group specializes in design, manufacturing, and marketing of a wide range of Textile machinery, it has seven branch companies, mainly produces ring spinning frame, roving frame, weaving machine (water Jet loom/Air jet loom/rapier Loom), warping machine, quilting machine and nonwoven machine. We provide design for complete line of spinning mill for cotton yarn, polyester yarn, wool yarn, flax/linen yarn, machines including blow room, carding machine, draw frame, roving frame, ring frame, winding machine, open end spinning machine and the air conditioning system and waste collection system for spinning mill. We also provide workshop layout design and trench design, and air pipe layout design. (2) Q: How's the after-sale service? A: We offer engineers available to service overseas under merchandiser's supervision and translation. (3) Q: Are you available for on-the-spot invitation? A: We do welcome our new and old friends come here to have a visitation. Besides, we would send you our exposition and relative information to promote a face-to-face meeting if you'd like to. (4) Q: Is the price offered changeable? A: We offer reasonable price for every client, and the price is changeable according to purchasing amount. (5) Q: How about the quality? A: The main subassembly and raw materials are all supplied by large companies. Key parts are research and developed by our own staff. Professional assembly line work and strict quality test system can ensure your high quality requirement. (6) Q: Are you a manufacturer or Trade Company? A: We are a professional manufacturer holding our own International Trade Department, for that we can better understand customer's needs and offer a reasonable price. (7) Q: Product /Quality Guarantee and After Sale Service? A: 1 year warranty for the International standard. We are work online 24 hours. If you have any questions about our machine you can contact us. (8) Q: One-stop Service: A: We have R&D department including more than 100 engineers which are improving and enlarging our supply range. (9) Q: Certification? A: TONGDA is an ISO9001, ISO14001, and ISO13485 company. The products are designed to meet the technical standards of 3C and CE. All the products are certified by the Industry Administration Authority. TONGDA will continue to strive to be a stronger leader in the global market of Cotton machinery and Spinning machinery.

Our clothing factory's logistics and transportation packaging is highly reliable. We have specially designed packaging according to equipment specifications, with strong protection and stable fixation to ensure transportation safety and ensure that the equipment arrives intact.

WhatsApp : +86 15207187668

Email:ZheyaCoLtd@outlook.com

Compartir